Introduction

Dust collection systems are an essential component of various industries, from woodworking to manufacturing and construction. They are designed to remove harmful dust and debris from the air, protecting workers from exposure to potentially hazardous particles. In this blog, we will discuss the importance of dust collection systems, the potential hazards of poor dust collection, and the purpose of the blog.

The importance of dust collection systems in various industries

Dust collection systems are critical in maintaining a safe and healthy work environment in various industries. These systems work by collecting dust and debris generated during industrial processes before it becomes airborne and inhaled by workers. Industries such as woodworking, metalworking, and construction generate a high volume of dust, which can be dangerous if not adequately collected. A dust collection system is essential in maintaining a clean and safe working environment for employees.

The potential hazards of poor dust collection systems

Poor dust collection systems can result in severe health hazards for employees, including respiratory problems, lung diseases, and even cancer. Prolonged exposure to dust and debris can cause long-term damage to the lungs and respiratory system. Additionally, uncollected dust can accumulate on surfaces and machinery, creating fire hazards and negatively impacting product quality. Poor dust collection systems can also lead to costly fines and penalties from regulatory agencies.

We will seek to highlight the importance of dust collection systems and to provide information on high-quality components that can be used to upgrade existing systems. The blog aims to help you understand the critical components of a dust collection system, the benefits of upgrading to high-quality components, and how to troubleshoot and maintain their systems. By providing you with this information, you will be able to improve workplace safety, enhance product quality, and reduce the risk of regulatory penalties.

The Basics of a Dust Collection System

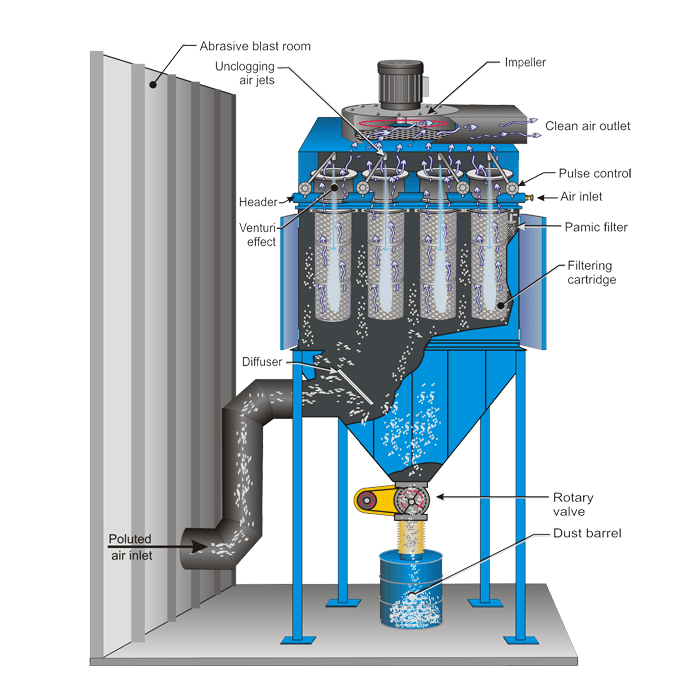

The working principle of a dust collection system

The working principle of a dust collection system is relatively simple. The system works by capturing the dust and debris at the source and moving it through the system to a collector, where it is either stored or disposed of. The system is powered by a fan or blower, which creates negative pressure within the system, pulling the dust and debris through the ductwork and into the collector.

The benefits of a properly functioning dust collection system

A properly functioning dust collection system provides numerous benefits, including:

- Improved air quality: A dust collection system removes harmful dust and debris from the air, improving air quality and reducing the risk of respiratory problems for employees.

- Enhanced product quality: Dust and debris can negatively impact product quality by contaminating surfaces and machinery. A dust collection system helps keep the workspace clean, reducing the risk of contamination and enhancing product quality.

- Increased workplace safety: Dust and debris can pose a fire hazard, and a dust collection system can help reduce the risk of fires in the workplace. Additionally, by removing harmful particles from the air, the system helps protect employees from exposure to hazardous materials.

- Compliance with regulations: Many industries are subject to regulations that require the use of a dust collection system to protect employee health and safety. A properly functioning dust collection system helps ensure compliance with these regulations, reducing the risk of costly fines and penalties.

The Components of a Dust Collection System

The different components and their importance in the system

Each component of a dust collection system plays a critical role in ensuring the system’s proper functioning.

- Hoods or capture devices: These components are essential in capturing dust and debris at the source. By capturing the contaminants at the source, they prevent them from becoming airborne, reducing the risk of exposure to employees and equipment. They come in various shapes and sizes and are designed to fit specific applications, such as sawing, sanding, or grinding. Examples of hoods or capture devices include blast gates, downdraft tables, and hooded sanding stations.

- Ductwork: The ductwork is responsible for transporting the dust and debris from the hood or capture device to the collector. Properly sized and designed ductwork ensures that the dust and debris are transported efficiently and without creating unnecessary resistance in the system. It comes in various materials such as metal, PVC, or flexible tubing. The size and shape of the ductwork are critical factors in ensuring that the system works efficiently.

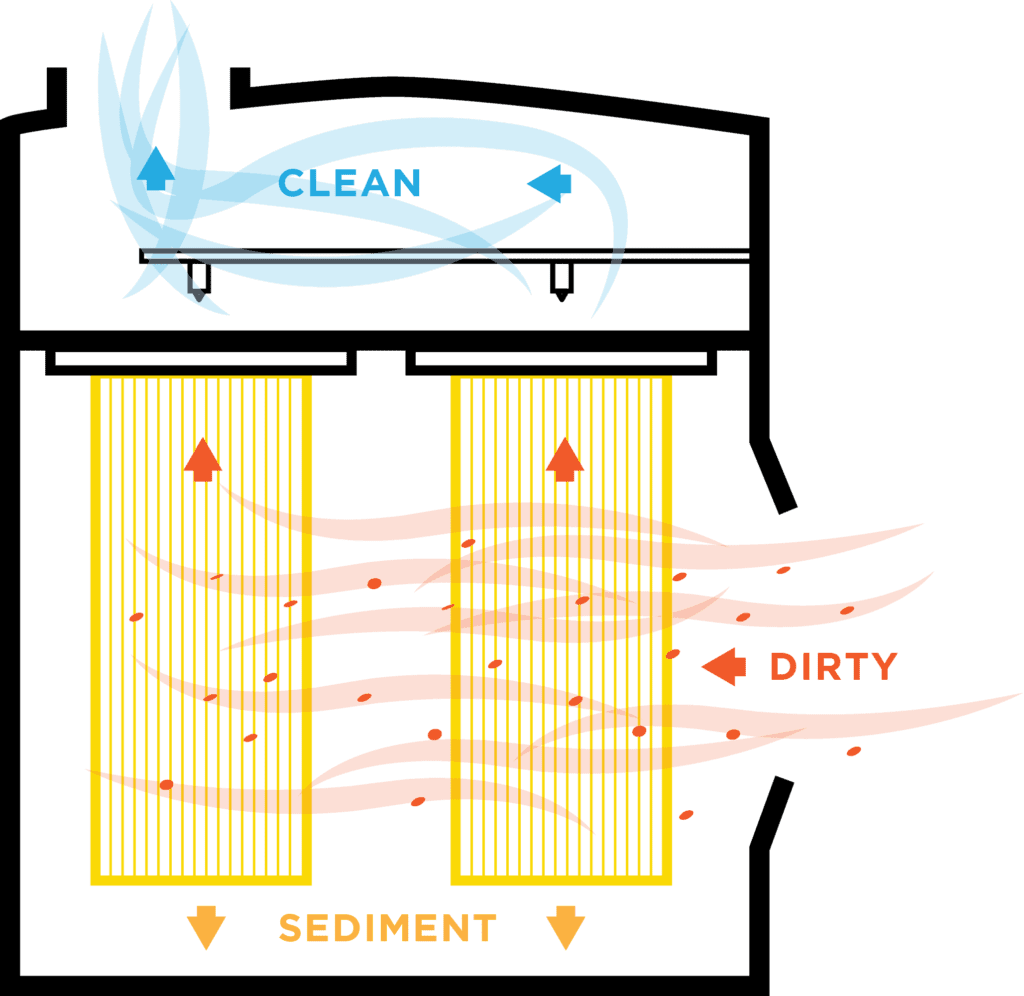

- Air cleaning devices: Air cleaning devices, such as filters and cyclones, remove the dust and debris from the air. They are essential components in ensuring that harmful particles are not released into the environment, protecting both employees and the surrounding community. They are essential components of a dust collection system as they prevent harmful particles from being released into the environment.

- Dust collectors: Dust collectors are responsible for collecting and storing the dust and debris that has been captured by the system. Properly functioning dust collector prevents the release of harmful particles into the environment and prevent the accumulation of dust and debris, reducing the risk of fire hazards and improving product quality. They come in various types, such as baghouses, cartridge collectors, and cyclone collectors. The type of dust collector chosen depends on the size and type of dust being captured.

Factors to Consider When Upgrading Your Dust Collection System

When upgrading a dust collection system, there are several factors to consider to ensure that the new system meets your needs and provides the best possible performance.

Application

The application of a dust collection system refers to the specific industrial process or operation that generates dust and other airborne particles. Different applications have unique dust collection requirements, which means that selecting the appropriate system components is critical in ensuring optimal performance.

For example, a woodworking shop may require a different baghouse dust collectors system than a metalworking shop. Woodworking generates fine wood dust that requires a system with high filtration efficiency, while metalworking generates larger and heavier metal particles that require a system with higher airflow capacity.

Other applications that may require specialized dust collection systems like wet dust collectors include pharmaceutical manufacturing, food processing, mining, and construction. Each application has unique dust collection requirements, such as the size of particles, the volume of dust generated, and the specific hazards associated with the dust.

It is essential to select components that are specifically designed for the type of dust being generated to ensure that the system functions optimally. For example, filters with high-efficiency ratings are suitable for fine dust particles, while larger particulate may require a cyclone separator or a pre-filter to capture larger particles before they reach the filter. The wrong components can result in reduced system efficiency, increased maintenance costs, and a higher risk of workplace hazards.

Consulting with a professional who specializes in dust collection systems can help ensure that the appropriate components are selected for the application. A professional can help determine the optimal system design, select the appropriate components, and ensure that the system is installed and maintained correctly.

Capacity

The size and capacity of the new system should match the requirements of the application. It is essential to consider the amount of dust being generated, the size of the equipment, and the number of operators when selecting a system.

Capacity is an essential consideration when upgrading a dust collection system. The capacity of a dust collection system refers to its ability to handle the volume of dust generated by the application. It is critical to choose a system with sufficient capacity to ensure that it can effectively capture and contain the dust generated.

To determine the appropriate capacity of a dust collection system, it is necessary to consider factors such as the volume of dust generated, the airflow rate required to capture the dust, and the size of the ductwork required to transport the dust from the source to the collector.

The airflow rate required to capture the dust depends on the nature of the dust and the application. For example, fine dust generated by sanding or grinding operations requires a higher airflow rate than larger particles generated by cutting or sawing operations. Additionally, larger applications will require larger dust collectors and larger diameter ductwork to handle the volume of dust generated.

It is important that you select a system with sufficient capacity to avoid overloading the system, which can result in decreased efficiency, increased maintenance costs, and increased risk of workplace hazards. An undersized system may not be able to handle the volume of dust generated, leading to inadequate collection and an increased risk of health hazards.

Similarly, an oversized system may be unnecessarily expensive and lead to unnecessary maintenance costs. An oversized system may not operate at peak efficiency and may require additional components to be added to achieve optimal performance.

When selecting a dust collection system, it is essential to consider the capacity requirements of the application and select a system that meets those requirements while ensuring efficient operation and minimizing costs. A professional who specializes in dust collection systems can help determine the appropriate system capacity and select the appropriate components to ensure optimal performance.

Efficiency

The efficiency of the system is crucial in ensuring that harmful particles are captured and filtered before being released into the environment. The selection of high-quality components and the proper design of the system can significantly improve its efficiency.

The efficiency of a dust collection system depends on several factors, including the design of the system, the components used, and the maintenance practices. A well-designed system with high-quality components and proper maintenance can operate at peak efficiency, providing optimal dust collection and minimizing the risk of health hazards.

One crucial component of a dust collection system that impacts efficiency is the filter. The filter is responsible for capturing the dust generated by the application, and its efficiency is determined by its ability to capture dust particles of various sizes. Filters with high-efficiency ratings are suitable for fine dust particles, while larger particulate may require a cyclone separator or a pre-filter to capture larger particles before they reach the filter.

Another factor that impacts efficiency is the air volume capacity of the system. The system must have sufficient airflow to effectively capture the dust generated by the application. An undersized system may not be able to handle the volume of dust generated, leading to inadequate collection and an increased risk of health hazards. Similarly, an oversized system may be unnecessarily expensive and lead to unnecessary maintenance costs.

Maintenance practices also play a critical role in ensuring the efficiency of a dust collection system. Regular maintenance, such as filter cleaning and replacement, can help ensure that the system operates at peak efficiency. Failure to maintain the system can result in decreased efficiency, increased maintenance costs, and an increased risk of workplace hazards.

When upgrading a dust collection system, it is essential to consider efficiency and select components that are designed to operate at peak efficiency. Working with a professional who specializes in dust collection systems can help ensure that the system is designed to operate at peak efficiency and that appropriate components are selected to achieve optimal performance.

Safety

The safety of employees is a critical factor to consider when upgrading a dust collection system. The new system should be designed to minimize the risk of accidents and ensure that employees are not exposed to harmful dust and debris. Poor dust collection systems can pose significant health and safety hazards to workers in industrial settings, particularly those who work in environments with high levels of dust and airborne particles.

One of the primary safety concerns related to dust collection systems is the risk of fire and explosion. Dust generated by certain applications, such as sawing, grinding, and sanding, can be highly flammable and combustible. Inadequate dust collection systems can accumulate dust particles, creating a potentially explosive environment. An effective dust collection system can help prevent the accumulation of combustible dust and minimize the risk of fire and explosion.

Another safety concern related to dust collection systems is the risk of exposure to harmful dust and airborne particles. Workers who are exposed to high levels of dust and airborne particles may be at risk of developing respiratory problems and other health issues, including lung cancer, asthma, and chronic obstructive pulmonary disease (COPD). Dust collection systems can effectively capture and contain these particles, reducing the risk of exposure and protecting worker health.

When upgrading a dust collection system, it is essential to consider safety and select components that are designed to minimize the risk of fire and explosion and protect worker health. Some high-quality components that can help enhance the safety of a dust collection system include explosion vents, spark arrestors, and fire suppression systems.

Working with a professional who specializes in dust collection systems can help ensure that the system is designed to minimize safety risks and that appropriate components are selected to achieve optimal performance. Regular maintenance and monitoring of the system can also help identify and address any safety concerns before they become a hazard to workers.

Cost

The cost of the system is an important consideration, and it is essential to balance the cost with the system’s performance and efficiency. A high-quality system may be more expensive upfront but can result in long-term cost savings through improved efficiency and reduced maintenance costs. Dust collection systems can vary greatly in cost, depending on the size of the system, the application, and the quality of the components used.

Upgrading a dust collection system can be a significant investment, but it is important to consider the long-term benefits and potential cost savings. A well-designed and properly functioning dust collection system can help reduce the risk of workplace hazards, increase worker productivity and comfort, and prolong the life of equipment.

When considering the cost of upgrading a dust collection system, it is important to take into account the cost of components, installation, and ongoing maintenance. While high-quality components may have a higher initial cost, they can provide long-term cost savings by reducing the need for frequent replacement and minimizing downtime.

The size and complexity of the dust collection system can also impact the cost of upgrading. Larger systems or those with more complex applications may require more components, installation time, and ongoing maintenance, increasing the overall cost of the system.

To minimize costs while still achieving optimal performance, it is important to select components that are designed to meet the specific needs of the application. Working with a professional who specializes in dust collection systems can help identify the most cost-effective components and system design for the specific application.

Regular maintenance and monitoring of the system can also help reduce overall costs by identifying and addressing potential issues before they become significant problems. A well-maintained system can operate at peak efficiency, reducing energy costs and minimizing the need for costly repairs and replacements.

While cost is a significant factor to consider when upgrading a dust collection system, it is important to consider the long-term benefits and potential cost savings of a well-designed and properly functioning system. Selecting high-quality components, working with a professional, and implementing regular maintenance and monitoring can help minimize costs while still achieving optimal performance.

The impact of upgrading on your workplace and employees

Upgrading a dust collection system can have a significant impact on the workplace and employees.

- Improved air quality: Upgrading to a high-quality dust collection system can significantly improve the air quality in the workplace, reducing the risk of respiratory problems and other health issues.

- Improved productivity: A properly functioning dust collection system can reduce downtime caused by equipment failures and maintenance, improving productivity and efficiency.

- Improved safety: Upgrading to a system with improved safety features can reduce the risk of accidents and injuries in the workplace.

How to select the right components for your system

Selecting the right components for your dust collection system is critical in ensuring its proper functioning and efficiency.

- Consider the application: The type of application and the nature of the dust being generated are critical factors in selecting the appropriate components for the system. It is essential to select components that are specifically designed for the type of dust being generated.

- Consult with a professional: Consulting with a professional who specializes in dust collection systems can help ensure that the system is designed and installed correctly. A professional can also help select the right components for the system including portable dust collectors.

- Research high-quality components: Researching high-quality components and brands can help ensure that the components selected are reliable and efficient. Reading reviews and consulting with other professionals in the industry can provide valuable insight into the best components for the system.

High-Quality Components for Dust Collection Systems

When upgrading a dust collection system, selecting high-quality components is essential to achieve optimal performance, efficiency, and safety. High-quality components can help minimize dust accumulation, reduce the risk of fire and explosion, protect worker health, and prolong the life of the system.

Some of the most important high-quality components for dust collector systems include:

Filters

Filters are one of the most critical components of a baghouse dust collector system. They are responsible for capturing and retaining dust particles, preventing them from being released into the air. High-quality filters can efficiently capture even the smallest particles, reducing the risk of exposure and improving air quality. Some popular types of filters for dust collection systems include pleated filters, bag filters, and cartridge filters.

Fans

Fans are used to create the suction required to move dust and particles through the collection system. High-quality fans can provide consistent airflow, reducing the risk of clogs and minimizing wear and tear on the system. Some popular types of fans for industrial dust collection systems include backward inclined fans, radial fans, and axial fans.

Ductwork

Ductwork also called dust collection hose is a system of pipes that transports dust and particles from the source to the collection system. High-quality ductwork can help maintain consistent airflow, reduce clogs, and minimize leaks. Some popular types of ductwork for dust collection systems include galvanized steel, stainless steel, and PVC.

Valves

Valves are used to control the flow of dust and particles through the collection system. High-quality valves can help prevent leaks and clogs, ensuring consistent performance and minimizing downtime. Some popular types of valves for dust collection systems include slide gates, butterfly valves, and rotary valves.

Explosion vents

Explosion vents are a critical safety component of dust collection systems, designed to release pressure in the event of an explosion. High-quality explosion vents can effectively vent pressure and prevent damage to the collection system and surrounding equipment. Some popular types of explosion vents for dust collection systems include flap vents, domed vents, and rectangular vents.

When selecting high-quality components for a dust collection system, it is important to consider the specific needs and requirements of the application. Factors such as the type of dust and particles being collected, the size and complexity of the system, and the safety and regulatory requirements of the industry should all be taken into account.

Some of the best options in the market for high-quality dust collection system components include reputable manufacturers such as Sofilt, Donaldson Torit, Camfil, and Nederman. These companies offer a wide range of high-quality filters, fans, ductwork, valves, and explosion vents, designed to meet the specific needs of various applications and industries.

Working with a professional who specializes in dust collection systems can also help identify the best components for a specific application and ensure that they are installed and maintained properly for optimal performance and safety.

Benefits of Upgrading Your Dust Collection System

Upgrading your dust collection system can offer numerous benefits to your workplace and employees. Here are some of the most significant benefits of upgrading your dust collection system:

Improved air quality

Upgrading your dust collection system like cartridge dust collectors with high-quality components can improve the quality of air in your workplace by capturing and removing harmful dust and particles from the air. This can reduce the risk of respiratory problems and other health issues caused by inhaling airborne particles.

Increased efficiency

Upgraded dust collection systems can offer higher efficiency and better performance, which can lead to improved productivity and reduced downtime due to equipment failure or maintenance.

Lower maintenance costs

Upgraded systems with high-quality components require less maintenance and repair, reducing maintenance costs and downtime due to repairs.

Enhanced safety

Upgraded dust collection systems can improve safety by reducing the risk of fire and explosion caused by the accumulation of combustible dust particles in the workplace.

Regulatory compliance

Upgraded dust collection systems with high-quality components can help you comply with local and national regulations for workplace safety and air quality.

Better working environment

Upgraded dust collection systems can create a cleaner, healthier, and more comfortable working environment for your employees, which can lead to improved morale and productivity.

The impact of an upgraded dust collection system on your workplace can be significant. An upgraded system can lead to improved production, increased efficiency, and a cleaner and safer working environment. This can reduce employee absenteeism, improve productivity, and enhance the overall quality of your products and services.

An upgraded dust collection system can also offer significant safety and health benefits to your employees. Exposure to airborne dust and particles can cause respiratory problems, eye irritation, and other health issues. Upgraded systems can remove harmful particles from the air, reducing the risk of these health problems and improving employee safety and well-being.

Maintenance and Troubleshooting of Your Dust Collection System

Maintaining and troubleshooting your dust collection system is essential to ensure optimal performance and prevent downtime. Here are some tips for maintaining your dust collection system and troubleshooting common issues that may arise:

- Regular maintenance: Regular maintenance is essential to ensure that your dust collection system continues to function at optimal levels. This includes replacing filters, checking for leaks, and ensuring that all components are functioning correctly.

- Monitoring system performance: Regularly monitoring the performance of your dust collection system can help you identify potential issues before they become significant problems. This includes monitoring the air flow, pressure, and temperature of the system.

- Keeping the system clean: Keeping your dust collection system clean is essential to ensure that it continues to function correctly. This includes cleaning the ductwork, hoods, and filters regularly.

- Training employees: Properly training employees on how to use and maintain the dust collection system can prevent issues and ensure that the system is functioning correctly.

Common issues that may arise with dust collection systems include:

- Clogging: Clogging is a common issue with dust collection systems, and it can occur when the filters become clogged with dust and particles.

- Leaks: Leaks can occur in the ductwork or other components of the system, leading to reduced performance and potentially hazardous conditions.

- Fan problems: Fan problems can occur when the fan motor fails, or the blades become damaged, leading to reduced airflow and performance.

- Electrical problems: Electrical problems can occur when the electrical components of the system, such as the control panel or motor, malfunction.

To troubleshoot and resolve issues with your dust collection system, follow these steps:

- Identify the issue: Identify the issue by monitoring the performance of the system and checking for signs of clogging, leaks, or other problems.

- Determine the cause: Determine the cause of the issue by inspecting the system for damage, leaks, or other issues.

- Repair or replace components: Repair or replace components as necessary to resolve the issue.

- Test the system: Test the system to ensure that the issue has been resolved and that the system is functioning correctly.

Conclusion

Upgrading your industrial dust collector system is a crucial investment that can bring significant benefits to your workplace. A properly functioning dust collection system helps to maintain a safe and healthy work environment, improve air quality, and increase the efficiency of your operations.

By upgrading your system with high-quality components, you can enhance its capacity, efficiency, and safety while reducing costs and downtime. The right components will ensure that your system performs at optimal levels, providing maximum protection against dust and other airborne pollutants.

Manufacturers are to take action and upgrade their dust collection systems with high-quality components. Don’t wait until it’s too late to protect your workplace and employees. Choose the right components that fit your needs and budget from the dust collection system suppliers and ensure that your system is operating at its best.

Contact Sofilt to help you through the process and ensure that you make the right investment for your business. With a properly functioning dust collection system, you can ensure a safe and healthy workplace for your employees and improve the overall efficiency of your operations.