Introduction

Workplace safety is important for any business, and one area that is often overlooked is the potential dangers of airborne particles. Cartridge dust collectors are an effective way to remove these particles from the air, but many people don’t understand how they work. In this blog post, we’ll take a comprehensive look at cartridge dust collectors and how they can keep your workplace safe.

What is a cartridge dust collector and how does it work

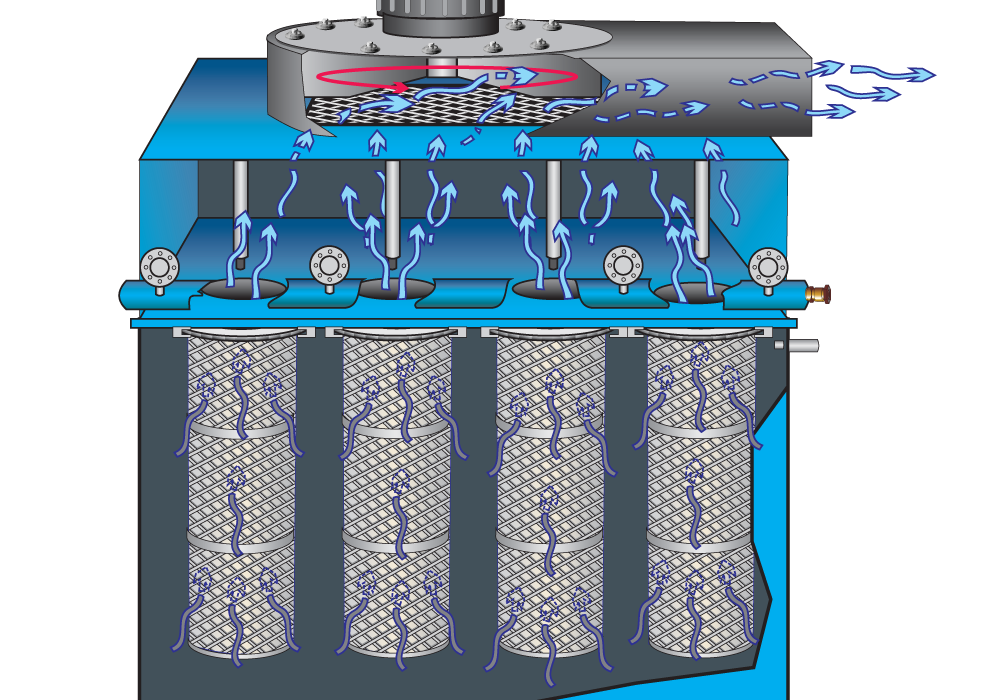

A cartridge dust collector is a highly efficient machine that traps and collects hazardous airborne particles from industrial processes. It works by drawing contaminated air into the system, where larger particles are dropped due to gravity and smaller particles are then collected on the filter media.

The filtered air is expelled back into the environment while the dust and particles are held inside the collector. Cartridge dust collectors are becoming increasingly popular in industries such as woodworking, metal fabrication, welding, agriculture and food processing due to their efficient and low-maintenance operation.

With its capability of removing all types of airborne contaminants, the cartridge dust collector can provide a safe and clean working environment while preserving employee health.

The benefits of using a cartridge dust collector

A cartridge dust collector is a type of air filtration system that is commonly used to control and remove dust, particulate matter, and other airborne contaminants from industrial and commercial environments. Some benefits of using a cartridge dust collector include:

High Efficiency: Cartridge dust collectors have a high-efficiency rating, meaning that they are able to remove a large percentage of dust and particulate matter from the air.

Low Maintenance: Cartridge dust collectors require minimal maintenance, making them a cost-effective solution for many industrial and commercial applications.

Compact Size: Cartridge dust collectors are compact in size, making them easy to install in a variety of settings, including those with limited space.

Customizable: Cartridge dust collectors can be customized to meet specific needs, making them an ideal solution for a wide range of industries and applications.

Easy to replace filter: Cartridge dust collectors are equipped with filter cartridges that are easy to replace, which means that the filter can be replaced quickly and efficiently, keeping the system running at peak performance.

Safe to use: Cartridge dust collectors are safe to use and don’t produce harmful by-products.

Energy efficient: Cartridge dust collectors are energy efficient, which means that they consume less power and produce lower operating costs.

Cost-effective: Cartridge dust collectors are relatively low-cost when compared to other types of dust collection systems.

The different types of cartridge dust collectors available

Choosing a dust collector for any workspace can be an intimidating task. There are several types of cartridge dust collectors available, each with its own unique features and benefits. Some of the most common types include:

- Pulse-jet Cartridge Dust Collectors: Pulse-jet cartridge dust collectors use compressed air to clean the filter cartridges. These systems are highly efficient, and they are able to remove a large percentage of dust and particulate matter from the air. They are suitable for high-volume applications, and can handle large volumes of air flow.

- Reverse-air Cartridge Dust Collectors: Reverse-air cartridge dust collectors use a reverse airflow to clean the filter cartridges. These systems are typically used in applications where the dust is highly abrasive or sticky, and they are able to handle high-volume air flow.

- Shaker-style Cartridge Dust Collectors: Shaker-style cartridge dust collectors use mechanical vibration to clean the filter cartridges. These systems are typically used in applications where the dust is light and fluffy, and they are able to handle moderate-volume air flow.

- Self-cleaning Cartridge Dust Collectors: Self-cleaning cartridge dust collectors use mechanical or pneumatic means to automatically clean the filter cartridges. These systems are typically used in applications where the dust is highly abrasive or sticky, and they are able to handle high-volume air flow.

- Mechanically-cleaned Cartridge Dust Collectors: Mechanically-cleaned cartridge dust collectors use mechanical means to clean the filter cartridges. These systems are typically used in applications where the dust is highly abrasive or sticky, and they are able to handle high-volume airflow.

- High-temperature Cartridge Dust Collectors: High-temperature cartridge dust collectors are used in applications where the dust is generated at high temperatures, such as in welding and meta lwork applications. These systems are able to handle high-volume airflow, and they are designed to withstand high temperatures.

- Explosion-proof Cartridge Dust Collectors: Explosion-proof cartridge dust collectors are used in applications where there is a risk of explosion, such as in the chemical and petrochemical industries. These systems are designed to be explosion-proof, and they are able to handle high-volume airflow.

- Portable Cartridge Dust Collectors: Portable cartridge dust collectors are designed to be moved from one location to another. These systems are typically used in applications where the dust is generated at multiple locations, and they are able to handle moderate-volume airflow.

All these types of cartridge dust collectors can come with different features, sizes, materials, and filtration efficiencies, the choice of the right cartridge dust collector would depend on the specific application, the process, and the level of dust/fume generated.

How to choose the right cartridge dust collector for your needs

Choosing the right cartridge dust collector for your needs can be a complex process, but by considering the following factors, you can ensure that you select the best system for your specific application.

- Volume of Air Flow: One of the most important factors to consider when choosing a cartridge dust collector is the volume of air flow that the system will need to handle. Make sure that the system you choose is properly sized for your specific application, and that it can handle the volume of air flow and dust that it will be encountering.

- Type of Dust or Particulate Matter: The type of dust or particulate matter that the system will be collecting is also an important factor to consider. Make sure that the filter cartridges used in the system are the correct type and size for your system, and that they are rated for the type of dust or particulate matter that you will be collecting.

- Filter Efficiency: The filter efficiency of a cartridge dust collector is an important consideration. The filter efficiency is the percentage of dust that is removed from the air. Look for a dust collector that has a high filter efficiency, typically above 99%.

- Pressure Drop: The pressure drop across the filter cartridges is another important factor to consider. A high pressure drop can indicate that the filter cartridges are clogged or dirty, and it can also increase the energy consumption of the system. Look for a dust collector that has a low pressure drop.

- Space Availability: The amount of space available for the dust collector is also an important consideration. Make sure that the system you choose will fit in the space you have available.

- Automation: Some dust collectors come with automation features that allow for remote monitoring and control, automatic filter cleaning, and automatic filter replacement. Consider if you need these features for your specific application.

- Noise Level: Noise level of the dust collector is also an important factor to consider. Make sure the dust collector you choose has a noise level that is acceptable for your specific application.

- Durability: The durability of the dust collector is also an important factor to consider. Make sure that the system you choose is made of high-quality materials and is designed to withstand the conditions of your specific application.

- Cost: The cost of the dust collector is also an important factor to consider. Look for a system that is within your budget, but also keep in mind that a more expensive system may have better features, better performance and longer lifespan.

- Consult the manufacturer: Consult the manufacturer for additional information and guidance about the best dust collector for your specific application.

By considering these factors, you can ensure that you select the best cartridge dust collector for your specific needs. It’s also important to make sure that you’re getting the right size of the dust collector and that you’re getting the right type of filter cartridge for the type of dust you’re trying to collect.

Tips for using and maintaining your cartridge dust collector

Using and maintaining a cartridge dust collector is essential to ensure that it operates efficiently and effectively. Here are some tips for using and maintaining your cartridge dust collector:

- Understand the System: Before using your cartridge dust collector, it is important to understand how the system works. This includes understanding the layout of the system, the type of filter cartridges used, and the control systems.

- Pre-clean the air: Before the air enters the dust collector, it should be pre-cleaned to remove larger particles. This can be done using a cyclone, a dust bin or a fabric filter.

- Use the Right Filter Cartridges: Using the right filter cartridges is essential for the proper operation of your cartridge dust collector. Make sure that the filter cartridges are the correct type and size for your system, and that they are rated for the type of dust or particulate matter that you will be collecting.

- Properly Size the System: Properly sizing your cartridge dust collector is essential to ensure that it can handle the volume of air flow and dust that it will be encountering. Make sure that the system is sized for your specific application and that it can handle the volume of air flow and dust that it will be encountering.

- Monitor the System: Regularly monitor your cartridge dust collector to ensure that it is operating efficiently and effectively. This includes monitoring the pressure drop across the filter cartridges, the airflow rate, and the system’s overall performance.

- Regularly Inspect the filter cartridges: Regularly inspect the filter cartridges to ensure that they are clean and in good condition. Look for signs of wear and tear, and replace the filter cartridges as needed.

- Regularly clean the filter cartridges: Regularly clean the filter cartridges to ensure that they are free of dust and debris. This can be done by using compressed air or a brush.

- Properly Store the filter cartridges: Properly store the filter cartridges when they are not in use to ensure that they do not become damaged or contaminated.

- Scheduled Maintenance: Schedule regular maintenance for your cartridge dust collector to ensure that it is operating efficiently and effectively. This includes cleaning the filter cartridges, inspecting the system for wear and tear, and replacing any parts that are worn or damaged.

- Consult the manufacturer’s manual: Always refer to the manufacturer’s manual for specific instructions on how to operate, maintain and troubleshoot the dust collector.

By following these tips, you can ensure that your cartridge dust collector is operating efficiently and effectively and that it is able to effectively remove dust and particulate matter from the air.

Conclusion

Understanding the cartridge dust collector is essential for choosing the right system for your specific application. Cartridge dust collectors are highly efficient and effective systems that are designed to remove dust and particulate matter from the air.

By considering factors such as the volume of air flow, the type of dust or particulate matter, filter efficiency, pressure drop, space availability, automation, noise level, durability, cost, and consulting the manufacturer, you can ensure that you select the best cartridge dust collector for your specific needs.

Additionally, regular maintenance, monitoring, and replacement of the filter cartridges can help to ensure the optimal performance of your cartridge dust collector over time. Here at Sofilt, we manufacture top-quality dust collector systems that are designed to meet your specific needs. We have been exporting our products to various countries across the world and aim to provide you with the best dust collection solutions. Contact us today for more information on our products or to discuss your dust collection needs. We look forward to helping you find the perfect solution.