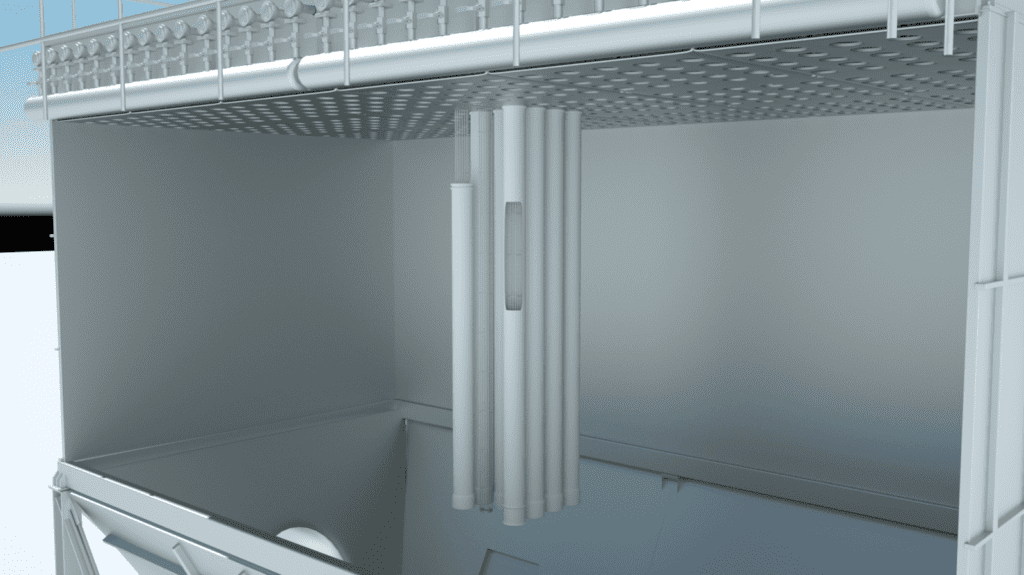

How does baghouse system work?

Baghouse filter bags are designed to capture dust particles from the air stream and store them until they can be disposed of or recycled. They are a very important component of a baghouse dust collector.

They’re made from woven or felted cloth and come in a variety of materials, sizes, and shapes. Baghouse filter bags are used in a variety of industrial, commercial, and residential applications. They’re used for everything from collecting sawdust in a woodshop to filtering the air in a factory.

What are baghouse filter bags and what do they do?

If you are looking for an effective way to filter dust, emissions, and other particulates from the air in your workplace, baghouse filter bags may be the solution for you. Baghouse filter bags are special fabric filters that are installed into baghouses and used to capture airborne particles in the surrounding air.

With baghouses containing multiple baghouse filter bags working together to trap dirt and debris, they offer a cost-effective method of filtering out unwanted pollutants from the environment. Quality baghouse filter bags can provide greater filtration efficiency than their lower-grade counterparts, helping your company achieve higher safety guidelines.

In addition, using baghouse filter bag replacements every few months is imperative to ensure they function at peak efficiency as they become clogged with captured particulates over time. Whether you’re running a manufacturing plant or need an air filtration system for another commercial establishment, baghouse filter bag solutions can help bring quality results while keeping costs down.

How Baghouse Filter Bags made

Baghouse filter bags are used in a variety of industrial applications, such as ore processing and cement production. These strong and durable machines are designed to remove airborne particles from the air stream by capturing them on the surface of the filter bags.

To ensure that these bags are up to the task, a wide range of materials can be used in their construction. Depending on their application, they may feature anything from cotton or polyester to Teflon or spun polypropylene.

Multi-filtration fabrics are an increasingly popular option, too, as they permit airflow while also trapping impurities at each layer. In general, baghouse filters rely on their finely woven material to catch particles with an efficiency rating as high as 99%.

To assemble the bags properly and place them correctly in the framework, manufacturers rely heavily on computer numerical control technology to quickly and efficiently shape each bag according to its individual specifications.

Seams and folds are typically reinforced with specialized stitching techniques so that each one is able to deliver reliable performance at all times – no matter how harsh the environment may be.

Ultimately, this complex manufacturing process allows for easy installation and maintenance – guaranteeing clean airflows with maximum uptime and minimal waste. Despite their complexity, Baghouse Filter Bags are surprisingly resilient – allowing you to run your machinery more efficiently for longer periods of time than ever before!

Types of Baghouse Filter Bags

There are different types of baghouse filter bags available for specific applications. Some of the more common materials used in making baghouse filter bags are polyester, nylon, acrylic, and glass fiber. Each of these materials has its own advantages and disadvantages in terms of its ability to capture dust particles and allow airflow. The type of baghouse filter bags used will depend on the application and environmental conditions. The most common types are:

Nylon Filters

Nylon filters are usually made with a resin-impregnated cloth which helps to keep dust particles from plugging the filter pores. They are also resistant to abrasion with very good resistance to alkalis and acids. Nylon filters can be used in many applications such as grain processing, mining, and air filtration.

Polyester Filters

Polyester filters are often used to capture fine dust particles in air filtration systems. They are strong and durable and have good resistance to acids, alkalis, and moisture. Polyester filters are available in a variety of micron ratings and can handle temperatures up to 250°F.

Acrylic Filters

Acrylic filters are made of a highly-durable, heat-resistant material which is great for applications where the filter is exposed to extreme temperatures. They are also very resistant to acids and alkalis. Acrylic filters are typically used in applications such as paint booths, meat packing plants, and paper mills.

Glass Fiber Filters

Glass fiber filters are made from a combination of glass fibers and acrylic binders. They have excellent resistance to abrasion and are highly effective at capturing dust particles. They can also handle temperatures up to 400°F and are very resistant to acids and alkalis. Glass fiber filters are often used in applications such as steel mills, food processing plants, and coal-fired power plants.

Polypropylene Filters

These are filters made from a combination of polypropylene and acrylic binders. They are very durable and offer excellent dust-capture capabilities. Polypropylene filters can handle temperatures up to 450°F and are resistant to most acids and alkalis.

They have a very smooth surface that provides good cake release and is resistant to blinding. You can find them in applications such as food manufacturing, chemical processing, and waste management.

How do I choose the right type of baghouse filter bag for my workplace?

Choosing the proper Baghouse Filter Bags for a particular application can be a daunting task, but it is essential for correctly controlling dust-bearing air streams and achieving optimal efficiency. When selecting Baghouse Filter Bags, the most important thing to consider is the particular application requirements and operating conditions of the particular system.

Picking the right type of baghouse filter bag for your particular system is not a decision to be made lightly. Baghouses serve a variety of important functions in most industrial environments, from helping regulate air quality to meeting applicable regulations. In order to make sure that you provide adequate filtration, you’ll want to choose an option that is resistant to abrasion and capable of handling a wide range of particles.

Depending on these factors, the right filter bags can vary considerably in material, size, shape, and rating. In general, heavier-duty filter bags should be used for higher temperatures or dust loads, while lighter-duty filter bags are suitable for lower temperatures or dust loads.

Of course, each type of bag must also offer sufficient retention efficiency to meet specific emission targets and reduce collection losses in the system. Additionally, careful consideration must also be given to issues such as abrasion resistance, chemical compatibility, and off-gassing potential if those might be factors in your system.

Finally, for many applications, there may also be regulatory requirements that need to be taken into account when choosing a filter bag type. With proper application expertise and an understanding of the specific needs of your system, you can ensure that you’re able to select the right Baghouse Filter Bags for any industrial operation.

Once all of these conditions have been taken into account, then you should consult with experts like Sofilt in order to decide what type of filter system will work best for your application. With the right understanding of your operation’s requirements and careful research into potential solutions, selecting the correct Baghouse Filter Bags can ensure safe operations and maximum efficiency.

Ultimately, though, it’s important to make sure your baghouse filter meets local requirements as well as the particular needs of your workplace before investing in its purchase or installation. With the right guidelines in mind and careful consideration for what type of media best fits each application, you can easily find the appropriate baghouse filter for your situation.

The most important item on any business’ checklist should always be safety first! Choose wisely and keep your workforce safe and healthy with an efficient yet economical baghouse filter.

The installation and maintenance of baghouse filter bags for optimal performance

Installing baghouse filter bags for optimal performance requires attention to detail and the right process. Before beginning any work, be sure to read the manufacturer’s instructions. If you don’t have an operator’s manual available, contact the company directly for one.

The bags should be securely fastened and installed in a smooth tube for an air-tight seal that prevents leakage and strong airflow into your system. Place the bag collar rings onto the tube sheet and secure them with bolts. Thereafter, inspect the seals properly to ensure there is a proper seal between the pipe sheet and each baghouse filter bag.

After installation, it is important to keep your filter bags maintained regularly to maximize their performance. Periodic cleaning and replacing worn-out components should minimize dust breakthroughs while limiting fire hazards by reducing spark loads on your system.

To avoid excess wear, use short pulse-jet blow cycles when cleaning out accumulated dust in your baghouse filter bags, as extended blowing may result in unnecessary damage of the material or elasticity of the fabric used in creating them. With regular maintenance, your baghouse filter bags should provide years of reliable performance for your system over time. So following these steps should ensure proper installation and safe ongoing operation of your facility.

What are some common problems with baghouse filter bags and how can you avoid them?

Baghouse filter bags are an important part of air filtration systems, used to capture and remove airborne particles, dust, smoke, and other contaminants from the air. However, baghouses can experience various issues if not properly cared for.

One common problem with baghouse filter bags is clogging due to the accumulation of built-up material on the surface. This causes a decrease in airflow efficiency and greatly reduces the filtering capacity.

Another issue is frequent wear and tear on the fabric of the bag itself – over time it can become brittle or deteriorate due to conditions like chemical exposure or extreme temperatures. Furthermore, birds and other animals may damage or nest among the bags; this can lead to tears and holes that let contaminants escape into the atmosphere.

To reduce these problems, inspect your filter bags regularly for any noticeable wear or damage; replace any that appear damaged or clogged; choose high-quality materials suited to your application, and use shields or other covers if necessary to protect your equipment from nesting wildlife. With good maintenance habits, you can help keep your baghouse operating at peak efficiency.

What benefits can Baghouse Filter Bags provide for industrial air filtration systems?

Industrial air filtration is an important process for maintaining a safe and healthy workplace. Baghouse filter bags are a proven solution used in a variety of industries to capture dust particles, toxins, and other contaminants at the source before they can be breathed in by employees.

In addition to eliminating contaminants from the air, baghouse Filter Bags have several other benefits. For one, their smooth fabric surface ensures maximum dust-holding capacity, meaning that fewer changes need to be made to the filter media over time.

Secondly, these bags are very efficient at capturing high concentrations of particulate matter due to their unique multi-pocket construction. Additionally, Baghouse Filter Bags allow for an optimal airflow when used in conjunction with a positive pressure system; this ensures that the entire filtration system works as efficiently as possible.

Finally, since these filters require minimal maintenance and have long lifespans, they’re cost-effective investments that are sure to save businesses money over time. All in all, Baghouse Filter Bags offer numerous advantages when it comes to industrial air filtration systems—advantages that cannot be overlooked.

Conclusion

The usefulness of Baghouse Filter Bags in industrial air filtration systems cannot be overstated. They’re highly efficient at capturing dust, toxins, and other contaminants, need minimal maintenance, and have long lifespans. Therefore, businesses should ensure that their filter bags are properly installed and maintained in order to maximize their performance and benefits.

Regular inspection and cleaning of the filter bags will help to avoid common problems such as clogging, wear and tear, and wildlife damage, ensuring a safe and healthy environment for employees. Investing in high-quality Baghouse Filter Bags is key to keeping your air filtration system operating optimally and efficiently. With regular maintenance, you can reap the many benefits that Baghouse Filter Bags provide for your business.

Even in health-critical applications, such as healthcare and pharmaceutical industries, Baghouse Filter Bags can be used to provide clean and safe environments. By investing in these durable filter bags, businesses can ensure the safety of their employees and customers.

Sofilt Baghouse Filter Bags are made with high-quality fabrics and designed to provide maximum dust-holding capacity, optimal airflow, and long service life. With a commitment to excellence in engineering, design, and manufacturing, Sofilt can help your business keep its air filtration system running safely and efficiently. Contact us today for more information about our Baghouse filter bags or for assistance selecting the right filter for your application.

Upgrading your air filtration system with Baghouse Filter Bags from Sofilt can make a real difference in the safety and cleanliness of your workspace. Investing in high-quality filter bags is an effective way to improve air quality and protect employees, customers, and other stakeholders. Contact us today to learn more about our Baghouse filter bags and how we can help keep your baghouse operating at peak efficiency.