Introduction

Replacement dust filter bags are specialized bags used in air filtration systems to trap dust, dirt, and other airborne particles. These bags are designed to be easily replaceable when they become clogged with debris, thus helping to ensure that the air filtration system continues to operate efficiently.

Clean indoor air quality is important for a variety of reasons. Poor indoor air quality can lead to respiratory problems, allergies, and other health issues. It can also contribute to the spread of illnesses and reduce productivity and cognitive function. By using filter bag housing with replacement dust filter bags, individuals can help to improve indoor air quality and promote a healthier environment as per the environmental protection agency of the state.

The science behind replacement dust filter bags is based on the principles of air filtration and reverse air. As compressed air is pulled through the filter bag, the fibers in the bag trap airborne particles, preventing them from circulating through the air. The efficiency of the filter material is determined by a variety of factors, including the size of the fibers, the density of the material, and the velocity of the air flow.

Replacement dust filter bags are designed to be highly efficient such as HEPA filters (high-efficiency particulate air) and to capture a wide range of particles, from large debris to microscopic allergens. Regularly replacing these bags helps to ensure that the air filtration system continues to operate effectively and maintain optimal indoor air quality.

Understanding Airborne Particles

Different types of airborne particles

Airborne particles can be classified into two main categories: solid and liquid. Solid particles can include dust, dirt, pollen, and various types of fibers. Liquid particles can include droplets from coughing, sneezing, or breathing, as well as vapors from chemicals or other substances. Both solid and liquid particles can vary in size, with some being large and visible to the naked eye, while others are microscopic.

How particles become airborne

Particles can become airborne through a variety of mechanisms. Solid particles can be kicked up by activities such as sweeping, vacuuming, or walking on carpets. They can also be introduced into the air through mechanical systems like HVAC systems, where they are circulated throughout the building. Liquid particles can be released through activities like coughing, sneezing, or talking, and can remain suspended in the air for long periods of time. Vapors can be released from sources like cleaning chemicals, paint, or other substances, and can linger in the air until they are removed by the air purifier, ventilation, or other methods.

Health effects of airborne particles

The health effects of airborne particles can vary depending on the size and type of particle, as well as the length of exposure. Large particles can cause irritation to the eyes, nose, and throat, while smaller particles can penetrate deeper into the respiratory system and cause inflammation and damage to the lungs. Exposure to certain types of particles, like asbestos or silica dust, can lead to serious lung diseases like asbestosis or silicosis.

Liquid particles like droplets from coughing or sneezing can also spread infectious diseases like the flu or COVID-19. In general, exposure to airborne particles can cause respiratory problems, exacerbate existing conditions like asthma or COPD, and contribute to a variety of health problems. It is important to take steps to minimize exposure to airborne particles, such as using air filtration systems with replacement dust filter bags, properly ventilating indoor spaces, and avoiding activities that can release particles into the air.

How Dust Filter Bags Work

Description of dust filter bags

Dust filter bags, also known as dust collector bags or filter socks, are dust control devices of industrial air filtration systems used to remove dust and other particles from the air. These bags are made of a porous fabric material that is designed to capture dust particles and prevent them from escaping into the environment.

The fabric used for dust filter bags is typically made of synthetic fibers such as polyester, polypropylene, or nylon. The fabric is usually formed into a cylindrical shape with a closed end and an open end that is attached to a metal or plastic ring. The ring is used to hold the bag in place within the air filtration system.

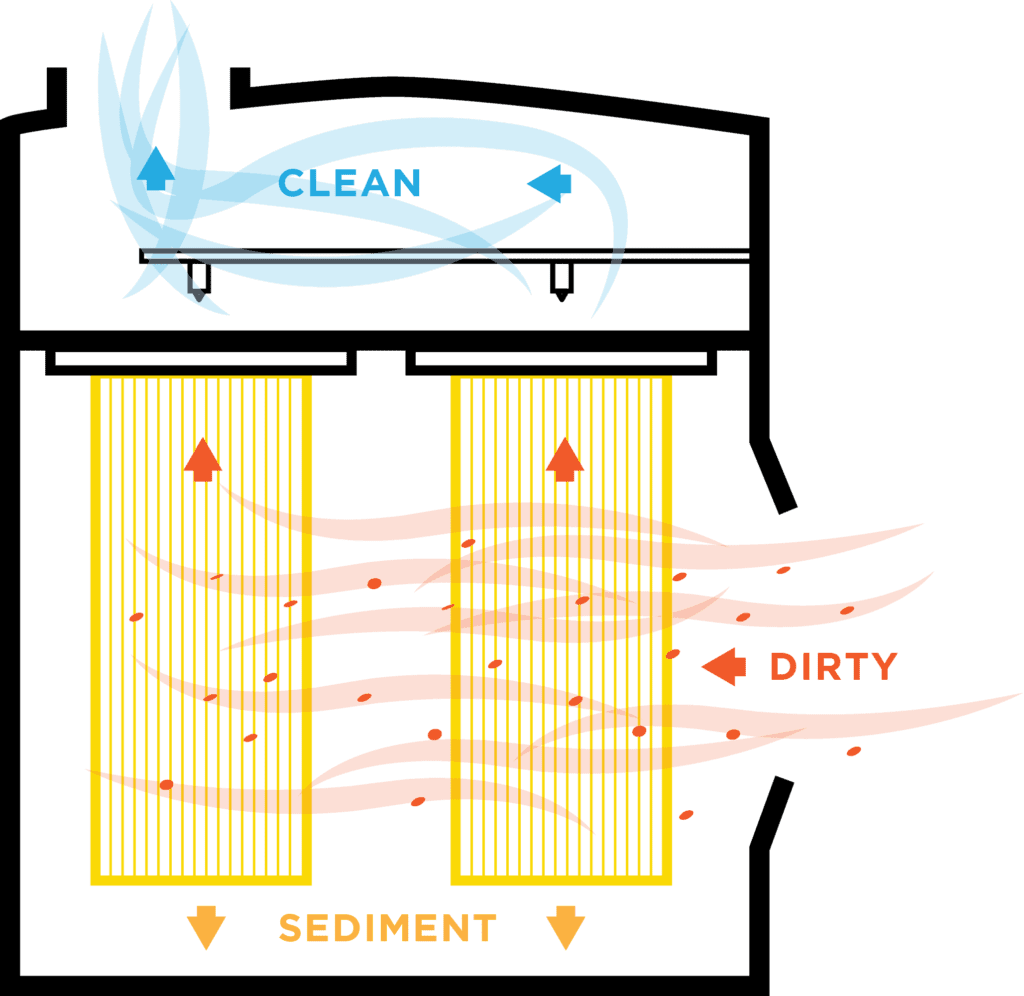

Mechanics of the filtration process

The mechanics of the filtration process in dust filter bags involve three basic steps: interception, impaction, and diffusion.

An interception occurs when a dust particle comes in contact with the fibers of the filter bag. The particle is captured by the fiber and held in place.

Impaction occurs when larger dirt particles are unable to pass through the filter and collide with the fibers. These particles are also captured and held in place.

Diffusion occurs when smaller dirt particles are unable to pass through the filter due to the random movement of gas molecules. These particles are also captured and held in place.

Over time, the accumulation of dust on the filter bag increases the resistance to airflow or pressure drop, and the bag must be cleaned or replaced to maintain the efficiency of the filtration system.

Types of dust filter bags and their differences

There are several types of dust filter bags available, each with its own specific characteristics and advantages.

- Polyester felt bag filter: These are the most commonly used dust filter bags due to their high efficiency and durability. They are resistant to chemicals, moisture, and abrasion.

- Polypropylene felt filter bags: These bags are used in applications where high temperatures and chemical resistance are required. They are also resistant to acids and alkalis.

- Nylon mesh filter bags: These bags are used in applications where a high degree of particle retention is required. They are also resistant to abrasion.

- PTFE membrane filter bags: These bags are used in applications where very high filtration efficiency is required, such as in the pharmaceutical and food processing industries. They are also resistant to chemicals and high temperatures.

- Fiberglass filter bags: These bags are used in applications where high temperatures and corrosive gases are present. They have high mechanical strength and chemical resistance.

Dust filter bags are essential components of industrial air filtration systems that are designed to capture and hold dust particles. The mechanics of the filtration process involve interception, impaction, and diffusion. There are several types of dust filter bags available, each with its own specific characteristics and advantages.

Importance of Using Replacement Dust Filter Bags

Dust bag filter is an essential component of dust collection systems used in various industries, such as woodworking, metalworking, and construction. These bags are designed to capture fine dirt particles and prevent them from being released into the air, improving indoor air quality and protecting the health of workers.

However, over time, dust filter bags can become clogged and dirty, reducing their effectiveness and posing various risks. In this article, we will discuss the importance of using replacement dust filter bags, including the effects of clogged and dirty bags, the advantages of using new bags, and the impact of high-quality bags on indoor air quality.

Effects of clogged and dirty dust filter bags

When dust filter bags become clogged and dirty, they can no longer effectively capture fine dust particles, which can result in various problems, including:

- Reduced air flow: Clogged dust filter bags can reduce the airflow in dust collection systems, causing the system to work harder to maintain proper suction. This can result in decreased productivity, increased energy costs, and even system failure.

- Dust leakage: When dust filter bags become too dirty, they can rupture or tear, allowing dust to leak out into the air. This can lead to a range of problems, including health risks to workers, increased maintenance costs, and potential fines for violating air quality regulations.

- Increased fire risk: Dust is highly combustible and can pose a significant fire risk in industrial settings. Clogged dust filter bags can increase the risk of dust explosions, which can result in serious injury or even death.

Advantages of using replacement dust filter bags

Using replacement dust filter bags offers several advantages, including:

- Improved dust collection: New dust filter bags are more effective at capturing fine dust particles, ensuring that the dust collection system is working efficiently.

- Increased productivity: By maintaining proper airflow and suction, replacement dust filter bags can help improve productivity and reduce energy costs.

- Lower maintenance costs: Regularly replacing dust filter bags can help prevent system failure and reduce maintenance costs over time.

- Compliance with regulations: Using high-quality replacement dust filter bags can help ensure compliance with air quality regulations, reducing the risk of fines and other penalties.

The impact of using high-quality dust filter bags on indoor air quality

Using high-quality dust bag filters can have a significant impact on indoor air quality. By capturing fine dust particles, these bags can prevent the release of harmful pollutants into the air, protecting the health of workers and improving overall air quality. Additionally, high-quality dust filter bags can help prevent the buildup of dust and other contaminants in the air, reducing the risk of respiratory issues, allergies, and other health problems.

Using replacement dust filter bags is crucial for maintaining a safe and healthy work environment. By preventing the negative effects of clogged and dirty bags, improving dust collection, and ensuring compliance with air quality regulations, replacement dust filter bags offer numerous benefits. Furthermore, using high-quality dust bag filters can have a significant impact on indoor air quality, improving the health and well-being of workers and reducing the risk of respiratory issues and other health problems.

Factors to consider when selecting replacement dust filter bags

When choosing the right replacement dust filter bags, there are several factors to consider:

- Type of dust: The type of dust being filtered is crucial in determining the type of filter bags to use. For instance, if the dust is fine and powdery, a filter bag with a high MERV rating may be required to ensure maximum filtration efficiency.

- Operating temperature: The operating temperature of the system also plays a role in determining the type of filter bags to use. High-temperature environments require filter bags made from materials that can withstand high temperatures.

- Airflow rate: The airflow rate is also essential when selecting replacement dust filter bags. The bag’s size and material should allow for sufficient airflow while still maintaining efficient filtration.

- Moisture content: If the dust being filtered has a high moisture content, filter bags made from materials that can resist moisture and prevent bacterial growth may be necessary.

- Chemical composition: The chemical composition of the dust being filtered can also impact the type of filter bags needed. For instance, if the dust is acidic or corrosive, filter bags made from materials that can resist corrosion and chemical damage may be required.

The importance of selecting the right size and type of filter bags

Selecting the right size and type of filter bags is essential to ensure maximum filtration efficiency and reduce the risk of system failure. If the filter bags are too small, they may not capture all the dust particles, leading to reduced filtration efficiency and increased wear and tear on the system. On the other hand, if the bag filters are too large, they may impede airflow, leading to reduced system performance.

The type of filter bags selected also plays a critical role in system performance. For instance, if such a system operates at high temperatures, filter bags made from high-temperature resistant materials such as Nomex or P84 may be required. Similarly, if the dust being filtered has a high moisture content, bag filters made from hydrophobic materials may be necessary.

The MERV ratings and the role of MERV ratings in selecting dust filter bags

MERV (Minimum Efficiency Reporting Value) ratings are a measure of a filter’s ability to capture and retain particles of a specific size range. MERV ratings range from 1 to 20, with higher ratings indicating better filtration efficiency.

The MERV rating plays a vital role in selecting the right replacement dust filter bags. A higher MERV rating means the filter bag can capture smaller particles, resulting in better filtration efficiency. However, filters with higher MERV ratings may impede airflow and require more frequent replacement, leading to increased maintenance costs.

For instance, a MERV 8 filter bag is suitable for filtering common household dust, while a MERV 14 filter bag may be necessary for filtering fine particulate matter such as pollen, mold spores, and bacteria. In contrast, a MERV 16 filter bag may be required for filtering ultra-fine particles such as smoke and viruses.

Selecting the right replacement dust filter bags requires consideration of various factors such as the type of dust, operating temperature, airflow rate, moisture content, and chemical composition. It is also crucial to select the right size and type of filter bags and to consider the MERV rating to ensure maximum filtration efficiency and reduce system failure.

Maintenance and Replacement of Dust Filter Bags

All workers involved in the process should receive proper training and education on the hazards involved and the proper safety protocols to follow. This can help prevent accidents and injuries and ensure that workers are prepared to handle any unexpected situations that may arise.

Safety should always be the top priority when replacing filter bags. By following appropriate safety protocols and taking necessary precautions, workers can minimize the risk of accidents and injuries and ensure that the process is completed safely and efficiently.

How often to change dust filter bags

The frequency at which dust filter bags should be changed varies depending on various factors such as the type of dust being filtered, the operating conditions of the system, and the type of filter bags used. However, in general, it is recommended to change dust filter bags at least every six months or more frequently if the system operates in harsh conditions or processes large volumes of dust.

Proper maintenance of dust filter bags

Proper maintenance of dust filter bags is essential to ensure maximum filtration efficiency and prolong the bags’ lifespan. Some maintenance tips include:

- Regular cleaning: Dust filter bags should be cleaned regularly to remove accumulated dust and debris. However, it is essential to use the proper cleaning techniques and equipment to prevent damage to the bags.

- Inspect the bags regularly: Regular inspection of the bags helps identify any signs of wear and tear or damage, allowing for timely repairs or replacement.

- Use high-quality bags: Using high-quality filter bags that are designed for the specific operating conditions of the system can help reduce wear and tear and prolong the bags’ lifespan.

- Proper installation: Proper installation of the filter bags is crucial to ensure maximum filtration efficiency and prevent damage to the bags.

The impact of regular replacement of dust filter bags on indoor air quality

Regular replacement of dust filter bags can significantly impact indoor air quality by reducing the amount of dust, allergens, and other contaminants present in the air. This is because dust filter bags play a crucial role in capturing and retaining particles in the air, preventing them from being recirculated into the indoor environment.

Moreover, regular replacement of dust filter bags can help prevent system failure, reducing the risk of costly repairs and downtime. This can help ensure that the system operates at peak performance, improving indoor air quality and creating a more comfortable and healthy indoor environment.

For instance, in industrial settings such as manufacturing plants or food processing facilities, regular replacement of dust filter bags can help prevent the release of harmful particles into the air, reducing the risk of respiratory illnesses among workers and ensuring compliance with health and safety regulations.

Proper maintenance and regular replacement of dust filter bags are essential to ensure maximum filtration efficiency, prolong the bags’ lifespan, and improve indoor air quality. It is recommended to change dust filter bags at least every six months or more frequently depending on the operating conditions of the system. Proper maintenance techniques such as regular cleaning, inspection, and proper installation can also help prolong the bags’ lifespan and improve system performance.

Conclusion

Replacement filter bags are an essential component of any air filtration system, playing a critical role in capturing and retaining harmful particles and contaminants in the air. The science behind filter bags involves the interaction between the filter media and the particles in the air, with factors such as the size and shape of the particles and the efficiency of the filter media influencing the filtration performance.

Choosing the right replacement filter bags and maintaining them properly can significantly impact the filtration efficiency and the indoor air quality, reducing the risk of respiratory illnesses and creating a more comfortable and healthy indoor environment. Therefore, understanding the science behind replacement filter bags is crucial in ensuring maximum filtration efficiency and creating a safe and healthy indoor environment for everyone.