Introduction

Dust collectors in the asphalt industry play a vital role in controlling the emission of dust and other particulate matter generated during the production and handling of asphalt products. These dust collectors are designed to capture and filter out dust particles, which can improve air quality in and around the asphalt plant, as well as comply with local and national regulations regarding air pollution.

There are different types of dust collectors used in the asphalt industry such as baghouse dust collectors, electrostatic precipitators, and wet scrubbers, each with its own set of benefits and maintenance requirements. The selection of the right dust collector depends on the specific requirements of the asphalt plant and the level of air pollution control desired.

The regular and proper maintenance of dust collectors is crucial to ensure their proper functioning and to prolong their lifespan. In this article, we will provide a comprehensive overview of the dust collectors in the asphalt industry including the types, benefits, maintenance, factors to consider when buying, and unique properties that make them suitable for the harsh environment of the asphalt industry.

Types of dust collectors used in the asphalt industry

Baghouse dust collectors

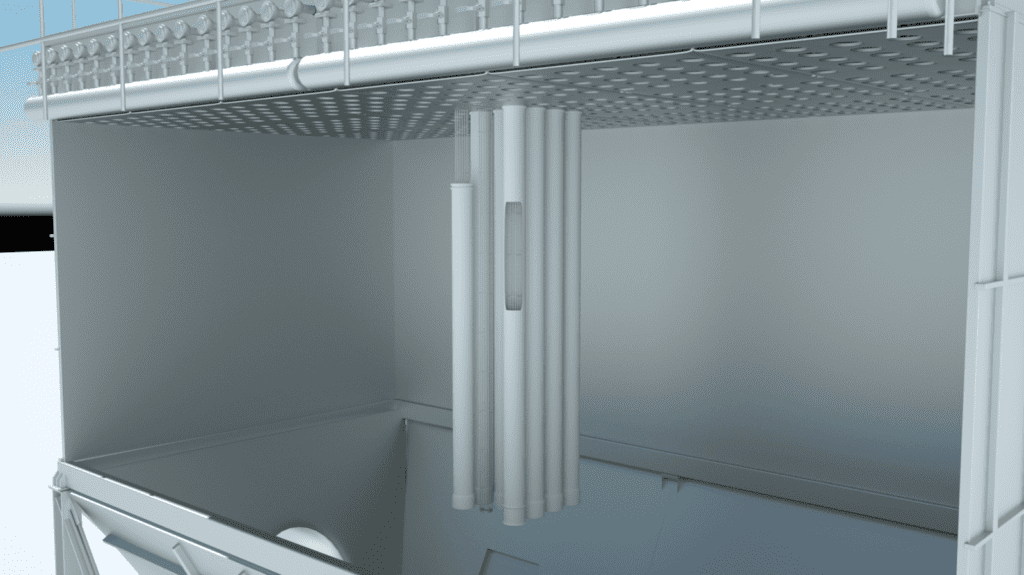

These are the most common type of dust collectors used in the asphalt industry. They work by drawing in dusty air through a filter bag, which captures the dust particles. The clean air is then released back into the atmosphere. Baghouse dust collectors are known for their high efficiency and durability, and they require relatively low maintenance.

Electrostatic precipitators

These dust collectors use an electrical charge to capture dust particles. As dusty air is drawn through the collector, the dust particles are given an electrical charge and are then attracted to a collection electrode. The collected dust is then removed from the collector. Electrostatic precipitators are known for their high efficiency and low maintenance requirements.

Wet scrubbers

These dust collectors use water to capture dust particles. As dusty air is drawn through the collector, the dust particles come into contact with water droplets, which cause the dust to adhere to the droplets. The collected dust is then removed from the collector. Wet scrubbers are known for their high efficiency and low maintenance requirements.

Features of dust collectors in the asphalt industry

Dust collectors in the asphalt industry are designed to capture and control the emission of dust and other particulate matter generated during the production and handling of asphalt products. These dust collectors have certain features and unique properties that set them apart from those used in other industries. These features include;

High-temperature resistance

Asphalt production often involves high temperatures, and dust collectors used in the asphalt industry are typically designed to withstand these temperatures. They may be constructed with heat-resistant materials, such as stainless steel, and may be equipped with cooling systems to prevent overheating.

Explosion-proof design

Asphalt production may generate dust and other particulate matter that is explosive, and dust collectors used in the asphalt industry are typically designed to be explosion-proof. This may include features such as flame arresters or spark detection and extinguishing systems.

High dust collection efficiency

Dust collectors used in the asphalt industry are typically designed to have a high dust collection efficiency. This may include features such as multiple stages of filtration or the use of electrostatic precipitation to capture dust particles.

Large air handling capacity

Asphalt production generates a large volume of dust and other particulate matter, so dust collectors used in the asphalt industry typically have a large air-handling capacity. This may include large filter bags or electrodes, or multiple stages of filtration.

Easy maintenance

As dust collectors in the asphalt industry are used in a harsh environments, they are designed to be easy to maintain. This may include features such as easy-to-replace filter bags or electrodes, or easy-to-access internal components for cleaning.

Durable construction

Dust collectors used in the asphalt industry are typically constructed with durable materials, such as stainless steel, to withstand harsh environments and to prolong their lifespan. These properties make them suitable for use in the harsh environment of the asphalt industry. By having these features, dust collectors used in the asphalt industry are able to provide reliable and efficient dust collection.

The benefits of dust collectors in the asphalt industry

There are several benefits of dust collectors in the asphalt industry, including:

- Improved air quality: Dust collectors help to improve the air quality in and around the asphalt plant by reducing the amount of particulate matter that is released into the atmosphere. This can lead to better working conditions for employees, as well as improved health and safety for people living and working in the surrounding area.

- Compliance with regulations: Dust collectors help asphalt plants to comply with local and national regulations regarding air pollution. This can help companies avoid costly fines and penalties for non-compliance.

- Reduced maintenance costs: Asphalt dust collectors require relatively low maintenance and can help to reduce the overall maintenance costs of the asphalt plant. This is because dust collectors can help to prolong the life of other equipment in the plant, such as dryers, screens, and conveyors.

- Increased productivity: Dust collectors used in the asphalt business can help in improving the overall productivity of the asphalt plant by reducing the amount of downtime caused by maintenance and repairs. This can lead to increased production and revenue for the company.

- Increased equipment lifespan: Dust collectors can help to prolong the life of other equipment in the plant by preventing dust and other particulate matter from entering and damaging the equipment. This can help to reduce the costs associated with equipment replacement and repairs.

- Energy savings: Asphalt dust collectors can help you reduce energy consumption by using filter bags or electrostatic precipitators to capture dust before it enters the equipment. This can help to reduce the load on the equipment and lower energy costs.

- Recycling of waste materials: Some dust collectors can be designed to recycle waste materials, such as dust and fines, back into the production process. This can help to reduce the costs associated with disposing of waste materials and increase the overall efficiency of the asphalt plant.

Maintenance of dust collectors in the asphalt industry

The maintenance of dust collectors in the asphalt industry is essential to ensure their proper functioning and prolong their lifespan. The specific maintenance requirements will vary depending on the type of dust collector being used, but some general maintenance tasks include:

- Regular inspections: Dust collectors should be inspected regularly to ensure that they are functioning properly and to identify any potential issues. This may include inspecting filter bags or electrodes, looking for signs of wear or damage, and checking for clogs or leaks.

- Cleaning or replacement of filter bags or electrodes: Dust collectors use filter bags or electrodes to capture dust particles, so it’s important to keep them clean and in good condition. This may involve removing the filter bags or electrodes and cleaning them with compressed air or a brush, or replacing them with new ones.

- Maintenance of the fan or blower: The fan or blower is responsible for moving air through the dust collector, so it’s important to keep it in good working condition. This may involve cleaning the fan or blower, checking the belts or bearings for wear, and replacing any damaged parts.

- Maintenance of the ductwork: The ductwork is responsible for carrying the air and dust through the dust collector, so it’s important to keep it in good condition. This may involve checking for leaks or blockages, cleaning the ducts, and replacing any damaged parts.

- Regular servicing: Regular servicing is important to keep the dust collector running efficiently and to identify any potential issues before they become major problems. This may include cleaning, oiling, and greasing the moving parts.

- Monitoring: Dust collectors come with control systems that monitor their performance, including filter pressure drop, airflow, and temperature. These should be monitored regularly to ensure the equipment is running correctly.

- Emergency planning: Dust collectors should have an emergency plan in place in case of power outages, equipment failure, or other emergencies. This may include having backup generators or other equipment on hand and training employees on how to safely shut down and restart the dust collector.

It is important to note that maintenance schedules for dust collectors will vary depending on the type of dust collector and the specific requirements of the facility. It is recommended to consult the manufacturer’s manual or consult an expert for specific maintenance schedules.

Regular and proper maintenance is critical for dust collectors in the asphalt industry. Regular inspections, cleaning, monitoring, and regular servicing are crucial to ensure that the dust collectors are functioning properly and to prolong their lifespan. Emergency planning should also be in place to ensure the safety of the employees and the equipment.

Factors to consider when buying a dust collector for the asphalt industry

There are several factors to consider when buying a dust collector for the asphalt industry, including:

- Airflow capacity: The airflow capacity of the dust collector should be sufficient to handle the amount of air and dust generated by the asphalt production process. This will depend on the size and production capacity of the asphalt plant and the specific dust collection requirements.

- Dust collection efficiency: The dust collection efficiency of the dust collector is an important factor to consider. This will depend on the type of dust collector, as well as the specific dust collection requirements of the asphalt plant. High-efficiency dust collection systems like baghouses, electrostatic precipitators, or wet scrubbers are suitable for the asphalt industry.

- Temperature and explosion resistance: As asphalt production often involves high temperatures, the dust collector should be able to withstand these temperatures. Additionally, the dust collector should be designed to be explosion-proof to protect against dust explosions.

- Maintenance and serviceability: The dust collector should be designed to be easy to maintain and service, minimizing downtime and maintenance costs. Features such as easy-to-replace filter bags or electrodes, or easy-to-access internal components for cleaning should be considered.

- Durability: Dust collectors used in the asphalt industry are exposed to harsh environments, so the dust collector should be constructed with durable materials, such as stainless steel, to prolong its lifespan. A strong and durable dust collector will also be safer and more reliable. By buying a quality dust collector, you can ensure that it will last for many years.

- Compliance with regulations: Dust collectors must comply with local and national regulations regarding air pollution. It is important to ensure that the dust collector meets these regulations and that the company can comply with them. Some countries may also have specific regulations regarding the specific types of dust collectors.

- Cost: The cost of the dust collector is an important factor to consider. The cost of the dust collector will depend on the specific features and requirements of the asphalt plant and the specific dust collection requirements. It is important to find a balance between the cost of the dust collector and the benefits it will bring to the company.

- Service and support: The service and support provided by the manufacturer of the dust collector should also be considered. This may include technical support, training, and service agreements. A good manufacturer will provide quality service and support to ensure that the dust collector performs as expected. In case of any issues, the manufacturer should be able to provide prompt assistance.

These are just some factors that need to be considered when buying a dust collector for the asphalt industry. It is essential to carefully weigh all these factors before making a purchase, in order to ensure that you get the most suitable dust collector for your needs.

In addition to the above factors, it is also important to ensure that proper safety protocols are in place when using the dust collector. Safety should always be a priority when dealing with the potentially hazardous materials that are used in the asphalt industry.

It is important to get the right dust collector for your asphalt production needs, in order to ensure that you are able to meet the air quality standards and regulations. Taking the time to consider all the above factors will help you to make an informed decision and ensure that you get the best dust collector for your needs.

Conclusion

Dust collectors are an essential part of the asphalt production process, and it is important to ensure that the right dust collector is chosen for your needs. Taking the time to carefully consider all the factors mentioned above will ensure that you get a quality dust collector that meets all your needs, and will help keep your asphalt plant running smoothly.

It is important to remember that safety should always be a priority in any production environment, and when dealing with hazardous materials like asphalt. Taking the necessary steps to ensure proper safety protocols are in place will help to prevent accidents and ensure that everyone stays safe.

With the right dust collector, you can ensure that your asphalt operations run smoothly and safely. Investing in a quality dust collector is an important step for any asphalt plant, and by taking the time to consider all the factors mentioned above, you can be sure that you are getting the best dust collector for your needs.

By understanding the importance of choosing a quality dust collector, you can ensure that your asphalt production runs efficiently and safely, while also meeting all air quality standards and regulations. Investing in a quality dust collector is an important step toward ensuring the success of any asphalt plant.

Sofilt is always ready to assist you in finding the right dust collector for your needs. Contact us today to learn more about our range of dust collectors and what they can offer you.