Introduction

Combustible dust hazards are a serious concern in many industries, including manufacturing, agriculture, and food processing. If not properly controlled, dust explosions can cause serious injuries and fatalities, as well as significant damage to equipment and facilities. Therefore, it is important for businesses to have a system in place for identifying and controlling combustible dust hazards.

The key steps to maintaining combustible dust hazards include:

Conducting a hazard assessment

Conducting a hazard assessment is an important step in identifying and controlling combustible dust hazards in your facility. A hazard assessment involves evaluating the potential for dust explosions in your facility and identifying the sources of combustible dust. This may include reviewing past incidents, analyzing the properties of the dust, and evaluating the design and operation of equipment and processes.

Some of the key steps involved in conducting a hazard assessment include:

- Identify sources of combustible dust: This may include process equipment, materials handling systems, and storage areas. Be sure to consider all areas of your facility, including production areas, offices, and storage areas.

- Evaluate the properties of the dust: Different types of dust have different explosive properties, and it is important to understand the specific characteristics of the dust in your facility. This may include its particle size, shape, and density, as well as its ignition temperature and sensitivity to ignition.

- Analyze the design and operation of equipment and processes: It is important to evaluate the design and operation of equipment and processes to identify potential sources of dust generation and to determine the potential for dust explosions.

- Review past incidents: If your facility has experienced dust explosions in the past, it is important to review these incidents to identify the root causes and determine what preventive measures should be put in place to prevent future incidents.

- Document your findings: Once you have completed your hazard assessment, it is important to document your findings and to develop a plan for controlling the identified hazards. This may include implementing preventive measures, such as installing dust collection systems or enclosing process equipment and establishing emergency response procedures.

Through hazard assessment, you can identify the sources of combustible dust in your facility and develop a plan for controlling these hazards to reduce the risk of dust explosions.

Implementing preventive measures

Once you have identified the sources of combustible dust in your facility, you should implement measures to prevent the accumulation of dust and reduce the risk of explosions. This may include installing dust collection systems, enclosing process equipment, and implementing good housekeeping practices.

Implementing preventive measures is an important step in controlling combustible dust hazards in your facility. Preventive measures are designed to reduce the risk of dust explosions by preventing the accumulation of dust and minimizing the likelihood of ignition.

Here are some examples of preventive measures that may be implemented in your facility:

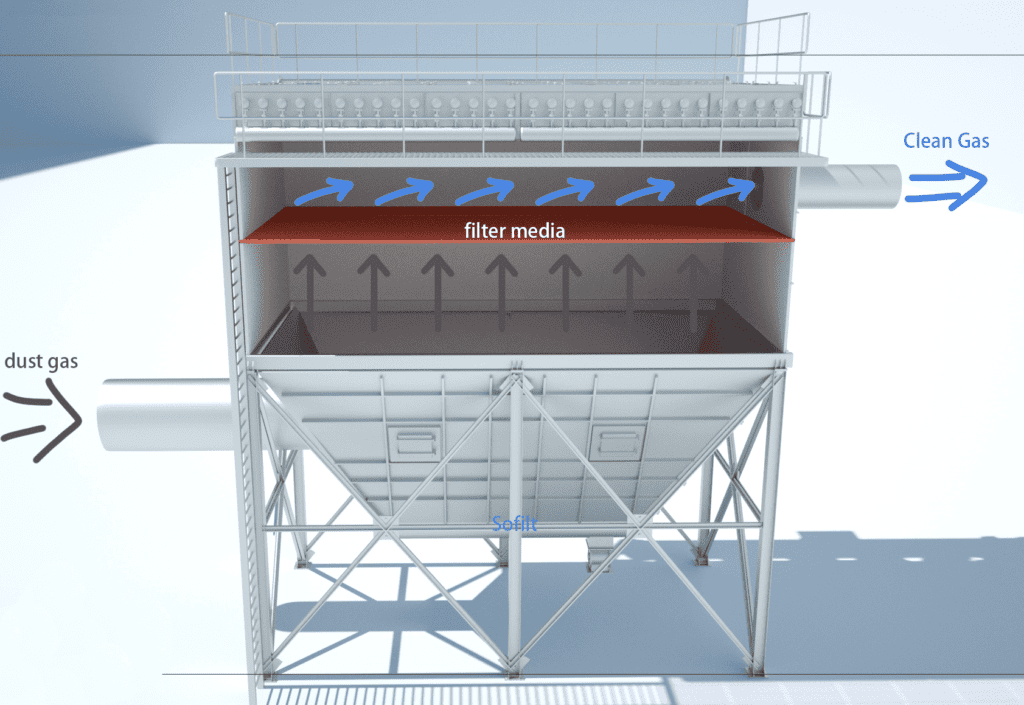

- Dust collection systems: Installing dust collection systems can help to reduce the accumulation of dust in your facility. These systems use fans, ductwork, and filters to collect and remove dust from the air, reducing the risk of dust explosions.

- Enclosing process equipment: Enclosing process equipment can help to prevent the release of dust into the air, reducing the risk of explosions. This may involve installing barriers or enclosures around equipment or using ventilation systems to remove dust from the air.

- Implementing good housekeeping practices: Maintaining a clean and orderly facility can help to reduce the accumulation of dust and minimize the risk of explosions. This may include regularly cleaning surfaces and equipment, and properly storing materials to prevent dust from accumulating.

- Using explosion-proof equipment: Using equipment that is designed to withstand dust explosions can help to reduce the risk of explosions in your facility. This may include using explosion-proof motors, lighting, and electrical outlets.

- Implementing proper ventilation: Proper ventilation can help to remove dust from the air, reducing the risk of explosions. This may involve installing ventilation systems or using exhaust fans to remove dust from the air.

These preventive measures can effectively control combustible dust hazards in your facility and reduce the risk of dust explosions. It is important to regularly review and update your preventive measures to ensure that they are effective and up-to-date.

Establishing emergency response procedures

It is important to have a plan in place for responding to a dust explosion in the event that one occurs. This may include procedures for evacuating the facility, shutting down equipment, and contacting emergency services.

Establishing emergency response procedures is an important step in managing combustible dust hazards in your facility.

The components of an emergency response plan for combustible dust explosions are:

- Evacuation procedures: Employees should be trained on how to safely evacuate the facility in the event of a dust explosion. This may include identifying multiple exits and safe areas and establishing a clear evacuation route.

- Shut-down procedures: It may be necessary to shut down equipment or processes in the event of a dust explosion. Employees should be trained on the appropriate procedures for shutting down equipment safely.

- Communication procedures: Employees should be aware of how to communicate an emergency situation to their supervisors and how to contact emergency services if necessary.

- Emergency response team: It may be beneficial to establish an emergency response team within your facility. This team should be trained in emergency response procedures and be responsible for coordinating the response to a dust explosion.

- Post-incident procedures: It is important to have a plan in place for addressing the aftermath of a dust explosion. This may include procedures for conducting an investigation, cleaning up debris, and repairing any damage.

Having emergency response procedures, you can ensure that your facility is prepared to effectively respond to a dust explosion and minimize the consequences of the incident. It is important to regularly review and update your emergency response plan to ensure that it is effective and up-to-date.

Providing training

All employees should be trained on the risks associated with combustible dust and the preventive measures that are in place to control these hazards. They should also be familiar with the emergency response procedures in case of an incident.

Providing training to employees is an important step in controlling combustible dust hazards in your facility. By educating employees on the risks associated with combustible dust and the preventive measures in place to control these hazards, you can help to ensure that they are aware of the potential dangers and know how to work safely.

Below are some key aspects of a training program for combustible dust hazards:

- Introduction to combustible dust: Employees should be provided with an overview of what combustible dust is and the potential dangers it poses. This may include information on the properties of combustible dust, the types of industries where it may be present, and the potential consequences of dust explosions.

- Prevention measures: Employees should be trained on the preventive measures that are in place to control combustible dust hazards in your facility. This may include information on dust collection systems, enclosing process equipment, and good housekeeping practices.

- Emergency response procedures: Employees should be familiar with the emergency response procedures in case of a dust explosion. This may include information on how to evacuate the facility, shut down equipment, and contact emergency services.

- Personal protective equipment: Employees should be aware of the personal protective equipment that is available to them and how to use it properly. This may include respirators, protective clothing, and other types of protective gear.

By providing comprehensive training to employees, you can help to ensure that they are aware of the risks associated with combustible dust and know how to work safely to prevent dust explosions. It is important to regularly review and update your training program to ensure that it is effective and up-to-date.

Regularly inspecting and maintaining equipment

Proper maintenance of equipment is critical to reducing the risk of dust explosions. Regularly inspecting and maintaining equipment is an important step in controlling combustible dust hazards in your facility.

Proper maintenance of equipment can help to reduce the risk of dust explosions by minimizing the generation of dust and preventing equipment failure.

Below are some key components of a maintenance program for controlling combustible dust hazards:

- Inspect equipment regularly: It is important to regularly inspect equipment for signs of wear or damage that could potentially lead to dust generation or equipment failure. This may include checking for loose or missing parts, and inspecting electrical components for signs of damage.

- Clean equipment regularly: Proper cleaning of equipment can help to reduce the accumulation of dust and minimize the risk of explosions. This may involve using vacuum cleaners, compressed air, or other methods to remove dust from equipment surfaces.

- Repair or replace damaged equipment: If equipment is damaged, it should be repaired or replaced as soon as possible to prevent the risk of dust explosions. This may involve replacing worn or damaged parts or repairing equipment that has been damaged in an accident.

- Follow manufacturer’s recommendations: It is important to follow the manufacturer’s recommendations for inspecting and maintaining equipment. This may include following a specific maintenance schedule and using specific cleaning and repair procedures.

Regularly inspecting and maintaining equipment, you can help to reduce the risk of dust explosions in your facility and ensure that equipment is operating safely. It is important to establish a comprehensive maintenance program and to adhere to it consistently to ensure the safety of your facility.

Reviewing and updating procedures

It is important to regularly review and update your combustible dust hazard control procedures to ensure that they are effective and up-to-date. This may involve revisiting your hazard assessment, implementing new preventive measures, and training employees on any changes.

Regularly reviewing and updating your combustible dust hazard control procedures is an important step in maintaining a safe and compliant facility. By revisiting your hazard assessment, implementing new preventive measures, and training employees on any changes, you can ensure that your procedures are effective and up-to-date.

Here are some important steps for reviewing and updating your procedures:

- Review your hazard assessment: It is important to periodically review your hazard assessment to ensure that it is still accurate and relevant. This may involve revisiting the sources of combustible dust in your facility, evaluating the properties of the dust, and analyzing the design and operation of equipment and processes.

- Implement new preventive measures: If you identify new hazards or opportunities for improvement during your review, it may be necessary to implement additional preventive measures. This may involve installing new dust collection systems, enclosing additional process equipment, or implementing new good housekeeping practices.

- Train employees on any changes: If you make changes to your hazard control procedures, it is important to provide training to employees on the new measures. This will ensure that they are aware of the changes and know how to work safely in accordance with the updated procedures.

- Review emergency response procedures: It is important to regularly review and update your emergency response procedures to ensure that they are effective and up-to-date. This may involve revisiting evacuation routes, shut-down procedures, and post-incident procedures.

By reviewing and updating your combustible dust hazard control procedures, you can ensure that your facility is prepared to effectively identify and control these hazards and minimize the risk of dust explosions.

Conducting drills and simulations

Regular drills and simulations can help you test and evaluate your emergency response procedures and identify any weaknesses or areas for improvement.

Conducting drills and simulations is important in testing and evaluating your emergency response procedures for combustible dust hazards. By simulating a dust explosion and practicing your response, you can identify any weaknesses or areas for improvement in your procedures and take corrective action to address them.

Some key procedures for conducting drills and simulations include the following:

- Determine the scope of the drill: It is important to determine the scope of the drill and what elements of your emergency response plan you want to test. This may involve simulating a full-scale dust explosion, or focusing on specific aspects of your response, such as evacuation procedures or shut-down procedures.

- Involve all relevant parties: It is important to involve all relevant parties in the drill, including employees, management, and any outside emergency response agencies. This will help to ensure that the drill is as realistic as possible and will provide an opportunity for all parties to practice their roles and responsibilities.

- Use realistic scenarios: To be effective, drills and simulations should use realistic scenarios that closely mimic the conditions that would be present in a real dust explosion. This will help to better prepare employees and emergency response teams for a potential incident.

- Evaluate the results: After the drill or simulation is complete, it is important to evaluate the results and identify any areas for improvement. This may involve reviewing how well the emergency response procedures were followed, identifying any communication issues, and identifying any areas where training may be needed.

Drills and simulations can test and evaluate your emergency response procedures and identify any weaknesses or areas for improvement. This can help to ensure that your facility is prepared to effectively respond to a dust explosion and minimize the consequences of the incident.

Conclusion

In conclusion, by following these steps, you can effectively identify and control combustible dust hazards in your facility and reduce the risk of dust explosions. It is important to remember that combustible dust hazards can be present in many different forms, and it is important to be vigilant in identifying and controlling these hazards to ensure the safety of your employees and facility.

If you need to replace any of the filter bags, Sofilt is always here to help. We are experts in the field of dust filtration and can provide you with the best quality filter bags for your needs. Contact us today to learn more about our products and services.

With our expertise and experience, we can ensure that your facility is properly equipped to identify and control combustible dust hazards, keeping your employees and facility safe and protected. If you have any questions or need advice about combustible dust hazard control procedures, please don’t hesitate to contact us for more information. We are here to help.