Introduction

Dust Filtration and its Importance

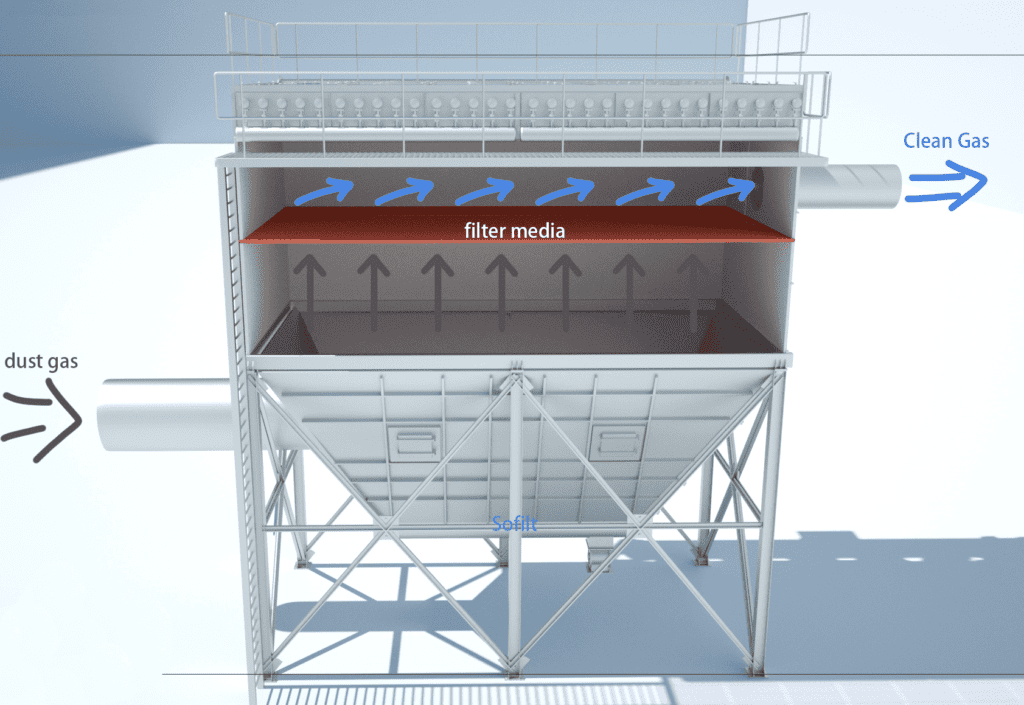

Dust filtration is the process of removing airborne particulate matter from an air stream. This process is crucial for maintaining a healthy and safe work environment in industries that produce dust, such as cement production, mining, and woodworking. Dust particles can pose a serious risk to the health of workers, as well as cause damage to equipment and machinery.

The importance of dust filtration cannot be overstated. The inhalation of dust particles can lead to serious health problems such as asthma, lung cancer, and other respiratory illnesses. In addition, dust particles can be combustible, leading to explosions or fires in certain industries. Therefore, effective dust filtration is essential for maintaining a safe and healthy work environment.

The Role of Filter Bags in Dust Filtration

Filter bags play a critical role in the process of dust filtration. These bags are designed to capture and hold dust particles as air passes through them. They are typically made from woven or felted materials such as cotton, polyester, or polypropylene.

Filter bags come in different shapes and sizes to fit various types of equipment, including baghouses, cartridge collectors, and dust collectors. They can be used in various industries such as cement, power, steel, and pharmaceuticals.

The Need for Innovative Filter Bag Materials

While traditional filter bag materials have been effective in capturing dust particles, they have several limitations. Traditional filter bags have a limited lifespan and can require frequent replacements, leading to increased maintenance costs. They can also become clogged easily, reducing their efficiency and air flow.

Innovative filter bag materials are necessary to overcome these limitations and improve the performance of dust filtration systems. These materials have unique properties that enhance their efficiency, lifespan, and cost-effectiveness. They can also improve air flow and reduce energy consumption, making them more sustainable and environmentally friendly.

Traditional Filter Bag Materials

Overview of Traditional Filter Bag Materials

Traditional filter bag materials are made from natural or synthetic fibers that are woven or felted together to create a porous fabric. Some of the most common traditional filter bag materials include cotton, wool, silk, nylon, polyester, and polypropylene. These materials are used to make filter bags for various industrial applications such as dust collection, air filtration, and liquid filtration.

Cotton filter bags are one of the most popular traditional filter bag materials due to their natural properties, which make them a good choice for filtering fine particles. Wool filter bags are also widely used, especially in high-temperature applications, due to their natural fire resistance. Silk filter bags are known for their ability to filter out very fine particles, making them a popular choice for liquid filtration. Nylon and polyester filter bags are known for their strength, durability, and resistance to chemicals, which makes them ideal for industrial applications.

Limitations of Traditional Filter Bag Materials

Despite their many benefits, traditional filter bag materials have some limitations that can impact their effectiveness in certain applications. One of the main limitations of traditional filter bag materials is that they can be prone to clogging. As particles accumulate on the surface of the filter bag, they can reduce its ability to capture additional particles, which can lead to decreased efficiency and increased maintenance.

Another limitation of traditional filter bag materials is their susceptibility to damage from chemical exposure, high temperatures, and other environmental factors. Over time, exposure to these conditions can weaken the fibers of the filter bag, reducing its strength and making it more susceptible to tearing and puncturing.

Common Problems Associated with Traditional Filter Bag Materials

One of the most common problems associated with traditional filter bag materials is a premature failure. This can occur when the filter bag is not designed to handle the specific conditions of the application, or when it is not properly maintained. Premature failure can result in increased downtime, higher maintenance costs, and decreased efficiency.

Another common problem associated with traditional filter bag materials is poor filtration performance. This can occur when the filter bag is not designed to capture the specific size and type of particles present in the application. Poor filtration performance can result in increased emissions, decreased efficiency, and decreased product quality.

In addition to these problems, traditional filter bag materials can also be difficult to install and remove, which can increase the time and cost of maintenance. They can also be heavy and bulky, which can make them difficult to transport and store.

Innovative Filter Bag Materials

Innovative filter bag materials have emerged in recent years to address the limitations of traditional filter bag materials. These materials are designed to offer superior filtration performance, longer lifespan, and improved air flow, among other benefits. Some of the most common types of innovative filter bag materials include nanofiber filter media, membrane filter media, and electrospun filter media.

Nanofiber Filter Media

Nanofiber filter media are made from ultra-fine fibers that are smaller than 1 micron in diameter. These fibers are typically made from materials such as polyethylene, polypropylene, or polyester, and are arranged in a non-woven structure. Nanofiber filter media offer superior filtration performance due to their small pore size, which allows them to capture even the smallest particles. They also offer improved air flow, which reduces energy costs and extends the life of the filter bag.

Membrane Filter Media

Membrane filter media are made from a thin layer of material that is applied to a substrate such as a non-woven fabric. This layer is typically made from materials such as polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), or polypropylene. Membrane filter media offer superior filtration performance due to their high surface area and small pore size. They also offer excellent chemical resistance and durability, making them ideal for harsh industrial environments.

Electrospun Filter Media

Electrospun filter media are made from a process called electrospinning, which involves using an electric field to create ultra-fine fibers. These fibers are typically made from materials such as polyethylene, polypropylene, or polyester, and are arranged in a non-woven structure. Electrospun filter media offer superior filtration performance due to their small pore size and high surface area. They also offer improved air flow and durability.

Benefits of Innovative Filter Bag Materials

Increased Filtration Efficiency

Innovative filter bag materials offer increased filtration efficiency due to their small pore size and high surface area. This allows them to capture even the smallest particles, resulting in cleaner air or liquids.

Longer Lifespan

Innovative filter bag materials offer a longer lifespan than traditional filter bag materials due to their superior durability and resistance to clogging. This reduces maintenance costs and downtime, leading to increased productivity and efficiency.

Improved Air Flow

Innovative filter bag materials offer improved air flow due to their high porosity and low resistance. This reduces energy costs and extends the life of the filter bag.

Cost-Effective

Innovative filter bag materials are often cost-effective due to their longer lifespan and improved efficiency. Although they may have a higher initial cost, the long-term savings in maintenance and energy costs make them a cost-effective solution for many industrial applications.

Applications of Innovative Filter Bag Materials

Cement industry

In the cement industry, filter bags are used for dust collection during the manufacturing process. Innovative filter bag materials are used to increase the efficiency and longevity of these bags. For example, PTFE (polytetrafluoroethylene) coated filter bags are commonly used in the cement industry because they can withstand high temperatures and are resistant to chemicals and abrasion. These bags are effective in capturing fine dust particles and can be used for a longer period, resulting in reduced maintenance and replacement costs.

Steel industry

In the steel industry, filter bags are used to control emissions from various processes, such as blast furnaces, electric arc furnaces, and sinter plants. Innovative filter bags materials like aramid fibers, fiberglass, and P84 have been developed for these applications. These materials have high-temperature resistance, chemical resistance, and good dimensional stability, which makes them suitable for use in the steel industry. For example, aramid fiber filter bags are used in steel mills to filter out harmful pollutants, such as heavy metals and sulfur dioxide, from exhaust gases.

Food and beverage industry

In the food and beverage industry, filter bags are used for the filtration of liquids, such as beer, wine, and juice. Innovative filter bag materials, such as nylon mesh and polypropylene, have been developed for these applications. These materials have good chemical resistance, are easy to clean, and can be reused, making them cost-effective. For example, nylon mesh filter bags are used in the brewing industry to filter out unwanted particles and ensure the clarity and quality of the beer.

Pharmaceutical industry

In the pharmaceutical industry, filter bags are used for the filtration of liquids and air. The innovative filter bag materials used in the pharmaceutical industry must meet strict regulatory requirements and be free of contaminants. For example, PTFE membrane filter bags are commonly used in the pharmaceutical industry for sterile filtration because they are highly efficient in capturing bacteria and other microorganisms. These bags have a high flow rate, are easy to clean, and can be sterilized, making them ideal for use in the production of pharmaceuticals.

Innovative filter bag materials are being developed and used in various environmental applications, particularly in air pollution control and waste management. Here are some examples of how these materials are being used:

Air Pollution Control

a. Nanofiber filter bags: These are made of nanofibers, which are tiny fibers with a diameter of less than 1 micron. They can capture particles as small as 0.1 microns and have a higher filtration efficiency than traditional filter bags. For example, a company called Hollingsworth & Vose developed nanofiber filter bags for diesel engine exhaust systems that can reduce emissions by up to 90%.

b. Activated carbon filter bags: These filter bags contain activated carbon, which is a highly porous material that can adsorb pollutants like volatile organic compounds (VOCs), mercury, and sulfur dioxide. Activated carbon filter bags are commonly used in industrial processes like chemical manufacturing, where VOCs are emitted.

Waste Management

a. Geotextile filter bags: These are made of synthetic or natural fibers and are used to filter and dewater sludge and other waste materials. Geotextile filter bags are commonly used in wastewater treatment plants, where they can be used to filter out solids from sludge before it is transported for disposal.

b. Biofilter bags: These are made of natural materials like wood chips, compost, or peat moss, and are used to treat organic waste streams like food waste and sewage sludge. The waste material is placed in the biofilter bag, and as it decomposes, it releases gases like methane and carbon dioxide. The biofilter bag contains microorganisms that consume these gases and convert them into harmless byproducts like water and carbon dioxide.

Innovative filter bag materials have a wide range of environmental applications, including air pollution control and waste management. Nanofiber and activated carbon filter bags are effective at capturing pollutants from industrial emissions, while geotextile and biofilter bags are useful for treating and managing waste materials. These materials are helping to reduce the environmental impact of industrial processes and waste management practices.

Future of Innovative Filter Bag Materials

Filter bag materials are used extensively in industries such as cement, pharmaceutical, food processing, and power generation, among others, to capture and filter dust and other airborne particles. The innovation and development of new filter bag materials have resulted in increased efficiency and sustainability in industrial dust filtration systems. In this context, let’s discuss the future of innovative dust filter bag materials, emerging trends, potential challenges, and opportunities, and their impact on the dust filtration industry.

Emerging Trends in Filter Bag Materials

a. Nanostructured filter bags: These bags are composed of nanofibers and have an increased surface area, allowing for better filtration of fine particles. This makes them more efficient than traditional filter bags.

b. Electrospun filter bags: Electrospinning is a technique used to produce nanofibers with a diameter of less than a micron. These fibers are then used to produce filter bags with a higher surface area for enhanced dust collection.

c. Sustainable filter bags: With the increasing focus on sustainability and reducing the carbon footprint, filter bag materials made from recycled or biodegradable materials are becoming more popular.

d. Intelligent filter bags: These bags have sensors that detect the amount of dust collected and alert the user when they need to be changed. This feature helps to reduce unnecessary filter changes and optimize filter usage.

Potential Challenges and Opportunities

a. Cost: Innovative filter bag materials are often more expensive than traditional materials, which may be a challenge for some businesses. However, the long-term benefits of increased efficiency and reduced maintenance costs may outweigh the initial cost.

b. Compatibility: New filter bag materials may not be compatible with existing filtration systems, requiring the installation of new systems, which can be a significant investment.

c. Market competition: As more companies invest in research and development of new filter bag materials, competition in the market is likely to increase, providing opportunities for innovation and better pricing.

d. Regulatory compliance: With increasing regulations around emissions and pollution, companies must ensure that their filtration systems meet these standards. Innovative filter bag materials can help companies achieve compliance.

Impact of Innovative filter bag on the Dust Filtration Industry

Innovative filter bag materials have the potential to transform the dust filtration industry by providing more efficient and sustainable solutions. This can lead to reduced maintenance costs, increased productivity, and improved environmental compliance. As businesses look to reduce their carbon footprint and increase sustainability, the demand for innovative filter bag materials is likely to increase. Additionally, as the dust filtration market becomes more competitive, companies that invest in the research and development of new filter bag materials will likely have a competitive advantage over others.

Importance of adopting innovative filter bag materials

Adopting innovative filter bag materials is essential for industrial air filtration for several reasons. Here are some of the key reasons why it is important to adopt these new materials:

Enhanced Filtration Efficiency

Innovative filter bag materials have higher filtration efficiency than traditional filter bags. This means that they can capture smaller particles, including those that are invisible to the naked eye. This is especially important in industries such as pharmaceuticals, food processing, and semiconductor manufacturing, where the air must be free of even the tiniest particles.

Improved Sustainability

Innovative filter bag materials can be made from recycled or biodegradable materials, which reduces the environmental impact of the filtration process. This is becoming increasingly important as more companies seek to reduce their carbon footprint and adopt sustainable practices.

Reduced Maintenance Costs

Innovative filter bag materials can reduce the frequency of filter replacements, which can lead to cost savings. Additionally, these materials are often more durable and can withstand harsher operating conditions, reducing the need for costly repairs or replacements.

Regulatory Compliance

Many industries are subject to strict regulations around air pollution and emissions. Innovative filter bag materials can help companies meet these regulations by providing higher filtration efficiency, reducing emissions, and improving air quality.

Improved Safety

Industrial air filtration is essential to protect workers from exposure to harmful airborne particles. Innovative filter bag materials can improve safety by capturing smaller particles that could otherwise be inhaled and cause respiratory problems.

Adopting innovative filter bag materials is critical to improving the efficiency, sustainability, and safety of industrial air filtration. As industries face increasing pressure to reduce their environmental impact and meet regulatory requirements, investing in new filter bag materials is a smart choice that can lead to cost savings, increased productivity, and improved environmental compliance.

Conclusion

Filtration is an essential process in various industries, and traditional filter bag materials have limitations that prevent them from delivering optimal filtration results. However, with the development of innovative filter bag materials, the filtration industry is undergoing a transformation that promises better results and improved efficiency.

This article has explored some of the emerging filter bag materials and their unique features and benefits. We have seen how these materials are being successfully implemented in various industries and processes, and the potential for their adoption in other areas.

Looking ahead, research and development efforts are ongoing, and the future looks promising for the filtration industry. With continued advancements in filter bag materials, we can expect to see even greater improvements in filtration performance and efficiency.

Businesses and industries using filtration should consider the benefits of innovative filter bag materials and explore their potential for improving their processes. With the right filter bag material, they can achieve optimal filtration results, reduce costs, and increase productivity.

Here at Sofilt, we are continuously investing in new filtration technologies that will improve the performance and accuracy of filtration systems. If you need help choosing the right filter bag material for your application, please don’t hesitate to contact us. We are always ready to assist you in making the best decision for your needs.