Introduction

Dust collection is a crucial aspect of any industrial or woodworking operation that involves creating dust or other airborne particles. It’s essential to maintain a clean and safe work environment for both the workers and the equipment. Dust can cause respiratory problems, fire hazards, and damage to machinery. Therefore, it’s vital to have an effective dust collection system in place.

Efficient dust collection is not only important for maintaining a safe work environment but also for improving productivity and reducing costs. Proper dust collection can improve air quality, prevent equipment breakdowns, and increase worker productivity by reducing downtime due to dust-related health issues. Moreover, it can significantly reduce maintenance costs associated with cleaning, repairing, and replacing equipment.

We will explore innovative dust collection design ideas that can maximize efficiency in your workplace. We will discuss various dust collection systems, equipment, and technologies that can help you achieve the most efficient dust collection possible. From cyclone collectors to baghouse filters, we’ll cover the different types of dust collection systems and their benefits.

Traditional Dust Collection Methods

The traditional dust collection methods that are commonly used in industries include cyclone collectors, baghouse filters, cartridge filters, and wet scrubbers. Cyclone collectors use centrifugal force to separate dust from the air stream, while baghouse filters capture dust on the surface of fabric bags. Cartridge filters use pleated cartridges to capture dust, and wet scrubbers use water to capture and neutralize dust particles.

While these traditional methods have been effective in collecting dust, they do have limitations. For example, cyclone collectors are less effective at capturing fine dust particles, and baghouse filters can become clogged and require frequent cleaning. Cartridge filters are expensive to replace and can be challenging to clean, while wet scrubbers can be costly to operate and require significant amounts of water.

Moreover, these traditional methods can be energy-intensive and can negatively impact air quality, particularly when used in conjunction with other dust collection methods. This can lead to increased costs, lower productivity, and a less safe work environment.

The Limitations of Traditional Dust Collection Methods and the Need for Innovation

The limitations of traditional dust collection methods highlight the need for innovative dust collection design ideas that can improve efficiency, reduce costs, and enhance air quality. Innovative dust collection technologies such as electrostatic precipitators, pulse-jet collectors, and high-efficiency particulate air (HEPA) filters can help overcome these limitations.

Electrostatic precipitators use an electrostatic charge to attract and capture dust particles, while pulse-jet collectors use compressed air to clean filters and maintain airflow. HEPA filters are highly effective at capturing fine dust particles and can be used in conjunction with other dust collection methods to improve air quality.

Innovative dust collection design ideas can also involve the use of IoT-enabled sensors and data analytics to monitor dust levels and optimize dust collection systems in real-time. This can help improve efficiency, reduce downtime, and lower operating costs.

Traditional dust collection methods have their limitations, and there is a need for innovative dust collection design ideas that can improve efficiency, reduce costs, and enhance air quality. By embracing these innovative ideas, industries can create a cleaner, safer, and more productive work environment for their employees.

Innovative Dust Collection Design Ideas

Recent years have seen the emergence of innovative dust collection design ideas that can significantly improve the efficiency of dust collection systems while reducing costs and enhancing air quality. Here are some of the most promising ideas:

IoT-enabled Dust Sensors

IoT-enabled dust sensors are a type of innovative dust collection design idea that has gained popularity in recent years. These sensors use Internet of Things (IoT) technology to provide real-time monitoring of dust levels in a given area, such as a factory or manufacturing plant. They are connected to a cloud-based system that collects and analyzes data from the sensors, enabling industries to optimize their dust collection systems in real-time.

IoT-enabled dust sensors offer several benefits over traditional dust monitoring methods. For example, they provide more accurate and timely data than manual monitoring, which can be time-consuming and prone to errors. The real-time data enables industries to quickly identify areas with high dust levels and adjust their dust collection systems accordingly, reducing energy consumption, and maintenance costs.

Moreover, IoT-enabled dust sensors can provide early warning of potential equipment failures, enabling proactive maintenance and reducing downtime. For example, if a sensor detects an increase in dust levels, it could indicate that a filter needs to be replaced or that there is a leak in the dust collection system. By addressing these issues proactively, industries can avoid costly downtime and repairs.

IoT-enabled dust sensors can also help industries comply with regulatory requirements. Many industries are required to monitor dust levels and maintain air quality standards, and IoT-enabled dust sensors can provide the data needed to demonstrate compliance with these regulations. Industries in various sectors have implemented IoT-enabled dust sensors with positive results.

For example, a cement manufacturer installed these sensors and optimized their dust collection system, reducing energy consumption by 30%. A steel manufacturer used IoT-enabled dust sensors to reduce maintenance costs and extend the life of their filters. These examples demonstrate the practicality and effectiveness of IoT-enabled dust sensors in improving dust collection system efficiency.

IoT-enabled dust sensors are an innovative dust collection design idea that offers many benefits, including real-time monitoring, proactive maintenance, and compliance with regulatory requirements. They have been successfully implemented in various industries, providing evidence of their effectiveness and practicality. By embracing this technology, industries can optimize their dust collection systems, reduce costs, and improve air quality for their workers.

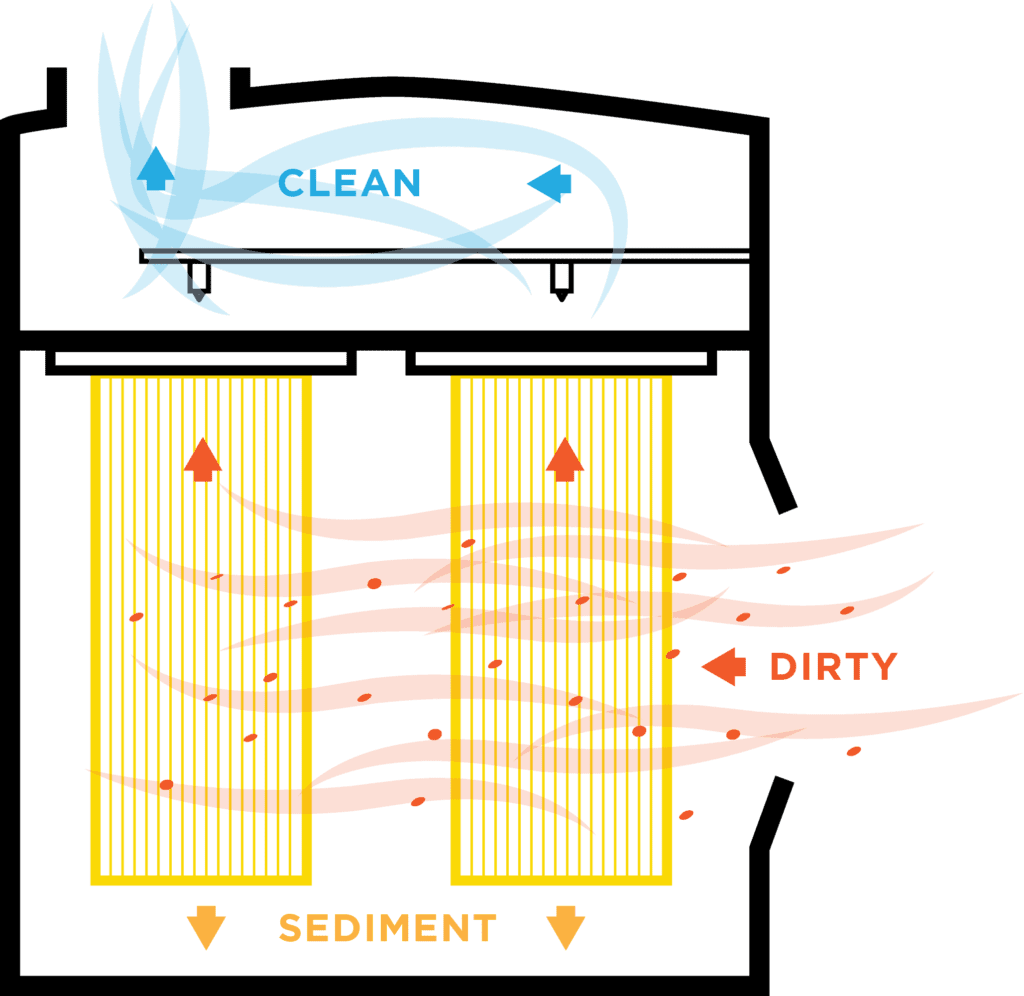

Reverse Air Dust Collectors

Reverse air dust collectors are a type of innovative dust collection design that can significantly improve the efficiency of dust collector system. These collectors use a unique reverse air flow to clean filters, reducing energy consumption and extending filter life. The process involves passing the airflow through the filter in reverse, dislodging the very fine dust particles from the filter’s surface, and collecting them in a hopper such as the wood dust.

One of the primary advantages of reverse air dust collectors is their ability to capture finer dust particles effectively. Fine dust particles are often difficult to capture using traditional dust collection methods, and they can accumulate on filters quickly, reducing their efficiency and increasing the frequency of filter replacement. Reverse air dust collectors can reduce the frequency of filter replacement and, in turn, reduce maintenance costs over time.

Reverse air dust collectors also use less energy compared to other dust collection methods. They typically require lower pressure drops across the filters, which reduces the energy consumption of the dust collection system. This not only saves on energy costs but also reduces wear and tear on the equipment, extending its lifespan.

Moreover, reverse air dust collectors are versatile and can be used in various industrial applications, including mining, woodworking dust, chemical processing, and food production. They are particularly useful in applications where high dust loads and high-temperature conditions are present.

Many industries have implemented reverse air dust collectors and seen significant improvements in their dust collection system’s efficiency. For example, a metal fabricator implemented a reverse air dust collector, reducing the frequency of filter replacement by 50% and extending filter life by two years. A chemical processing plant implemented a reverse air dust collector, reducing energy consumption by 25%.

Reverse air dust collectors are an innovative dust collection design that offers many benefits, including effective capture of fine dust particles, reduced maintenance costs, lower energy consumption, and versatility in various industrial applications. They have been successfully implemented in various industries, providing evidence of their effectiveness and practicality. By embracing these technologies, industries can optimize their dust collection systems, reduce costs, and improve air quality for their workers.

Rotary Valves

Rotary valves are a type of innovative dust collection design idea that is widely used in the industry to collect dust. These valves help to regulate the flow of dust and other materials through a dust collection system. They are designed to prevent material from backing up into the dust collection equipment and to maintain a consistent and efficient flow of material throughout the system.

Rotary valves are typically located at the bottom of hoppers or silos, where they serve as an outlet for the material contained within. They are designed to operate continuously, with the valve rotating at a constant speed to regulate the flow of material through the system.

One of the primary benefits of rotary valves is their ability to handle high volumes of material without clogging or jamming due to reduced static pressure. They are designed to prevent the material from accumulating in the valve, dust port or hopper, ensuring a consistent flow of material through the system. This helps to maintain the efficiency of the dust collection system and reduces the need for maintenance and cleaning. Rotary valves can also help to reduce energy consumption in dust collection systems.

By maintaining a consistent flow of material, they reduce the pressure drop across the system, which in turn reduces the amount of energy required to operate the system. This can result in significant energy savings over time, making rotary valves a cost-effective solution for industrial dust collection systems.

Additionally, rotary valves are available in a wide range of sizes and configurations to accommodate various industrial applications. They can be designed to handle high temperatures, corrosive materials, and other challenging conditions. This makes them a versatile solution for dust collection in many different industries, including food processing, mining, and chemical processing.

Many industries have implemented rotary valves and seen significant improvements in their dust collection system’s efficiency. For example, a cement plant implemented rotary valves and reduced the frequency of valve cleaning by 90%, resulting in significant cost savings.

High-efficiency Cyclones

High-efficiency cyclones are a type of dust collection technology that uses centrifugal force to separate dust particles from a gas stream. These cyclones are designed to achieve high separation efficiency while minimizing pressure drop and energy consumption. High-efficiency cyclones are commonly used in a variety of industries, including cement, mining, pharmaceuticals, and food processing.

The design of high-efficiency cyclones typically includes a cylindrical or conical vessel with an inlet for the gas stream and an outlet for the cleaned gas. The gas stream enters the cyclone tangentially, creating a swirling motion that separates the dust particles from the gas. As the gas swirls around the cyclone, the particles move toward the walls of the vessel due to centrifugal force. The particles then fall to the bottom of the cyclone and are collected in a hopper, while the cleaned gas exits through the outlet at the top of the cyclone.

High-efficiency cyclones are characterized by their high separation efficiency, which is typically in the range of 80-95%. This means that they can effectively remove a large percentage of dust particles from the gas stream, even those as small as 10 microns. The high separation efficiency is achieved by optimizing the design of the cyclone, including the dimensions of the vessel, the inlet and outlet sizes, and the shape of the vortex finder and cyclone body. In addition, the use of specialized materials and coatings can further improve the separation efficiency of high-efficiency cyclones.

Another advantage of high-efficiency cyclones is their low pressure drop, which refers to the difference in pressure between the inlet and outlet of the cyclone. A lower pressure drop means that less energy is required to operate the cyclone, resulting in lower operating costs and energy consumption. High-efficiency cyclones can achieve pressure drops as low as 2-3 inches of water column (wc), compared to conventional cyclones, which typically have pressure drops of 6-10 inches wc.

Benefits of innovative Dust collection design

Innovative dust collection design ideas can lead to significant improvements in the efficiency of dust collection systems. Effective dust collection is essential in many industries to maintain a safe and healthy work environment and comply with environmental regulations. Innovative dust collection design can offer several benefits, which we will discuss below.

Improved efficiency and cost savings

Innovative dust collection design can significantly improve the efficiency of dust collection systems, reducing energy consumption and operating costs. For example, a well-designed dust collection system can reduce the need for manual cleaning, maintenance, and repairs, saving time and money in the long run. Furthermore, by improving the separation efficiency of the dust collection process, innovative designs can also reduce the amount of waste material, leading to further cost savings.

Enhanced safety

Dust collection systems are essential for maintaining a safe work environment, especially in industries such as woodworking, metalworking, and food processing. Innovative dust collection designs can significantly improve the safety of these systems by reducing the risk of explosions and fires. For instance, the use of spark arrestors, explosion vents, and chemical inhibitors can help prevent dust explosions and fires, protecting both workers and equipment.

Increased reliability

Innovative dust collection designs can also improve the reliability of dust collection systems, reducing downtime and increasing productivity. For example, modular dust collectors with interchangeable parts and components can simplify maintenance and repairs, allowing for quick and easy replacement of faulty or worn-out components.

Better air quality

Innovative dust collection designs can also improve the quality of indoor air in the workplace. By removing dust particles and other contaminants from the air, these systems can reduce the risk of respiratory problems and allergies among workers. Additionally, some dust collection systems can be equipped with air filtration devices that remove even the smallest particles, further improving air quality.

Compliance with regulations

Many industries must comply with strict environmental regulations concerning air quality and emissions. Innovative dust collection designs can help companies meet these requirements by reducing emissions and improving air quality. This compliance can also help companies avoid fines and penalties for non-compliance.

Factors to Consider When Designing a Dust Collection System

Designing an effective and efficient dust collection system requires careful consideration of several factors. Below are some of the most important factors that need to be considered when designing a dust collection system:

Type of dust

Different types of dust have different characteristics that can affect the dust collection system’s performance. For example, fine dust particles are more difficult to capture than larger particles, and some dust may be more abrasive or corrosive than others, which can affect the equipment’s durability. The dust’s combustibility is also an important factor to consider in applications where explosive dust can pose a safety risk.

Airflow rate

The airflow rate is the amount of air that passes through the system, and it is critical in determining the system’s effectiveness in capturing dust. The airflow rate must be sufficient to capture all the dust generated by the process while maintaining a minimum air velocity that prevents the settling of the dust in the ductwork.

Ductwork design

The design of the ductwork is critical in ensuring efficient dust collection. The ductwork must be designed to maintain the required airflow rate and velocity while minimizing pressure drops, which can reduce the system’s efficiency. The ductwork must also be designed to prevent clogging or blockages, which can reduce the system’s effectiveness.

Filter efficiency

The efficiency of the filters used in the dust collection system is another critical factor to consider. Filters are designed to capture dust particles, and their efficiency determines how effectively the system can remove dust from the air. The type of filter used, its size, and the frequency of cleaning or replacement must be carefully considered to ensure the system’s effectiveness.

These factors can impact the effectiveness and efficiency of the dust collection system in several ways. For example, inadequate airflow rates can lead to dust settling in the ductwork, reducing the system’s effectiveness. Poor ductwork design can also lead to clogging and blockages, reducing the system’s efficiency. Inefficient filters can lead to poor capture of dust particles, reducing the system’s effectiveness in removing dust from the air.

To optimize the design of the dust collection system, it is essential to consider these factors carefully. Proper consideration of the type of dust, airflow rate, ductwork design, and filter efficiency can help ensure that the system is effective and efficient in capturing dust and removing it from the air. A well-designed system can help reduce worker exposure to dust, improve air quality, and promote a safe and healthy work environment.

Conclusion

Dust collection is a critical aspect of maintaining a clean and safe work environment in many industries. Traditional dust collection methods have limitations that can be addressed through innovation, and several innovative dust collection design ideas have emerged in recent years that can improve the efficiency and effectiveness of dust collection systems.

We discussed several innovative dust collection design ideas, including IoT-enabled dust sensors, reverse air dust collectors, rotary valves, and high-efficiency cyclones. Each design idea has unique features and benefits that can improve the system’s performance and reduce costs in the long run. We also highlighted the importance of considering factors such as the type of dust, airflow rate, ductwork design, and filter efficiency when designing a dust collection system.

Efficient dust collection is essential for worker safety, reducing the risk of respiratory problems and other health issues associated with exposure to dust. It can also improve productivity and reduce costs by reducing equipment wear and tear, minimizing downtime, and lowering maintenance costs.

As technology advances, new dust collection design ideas will continue to emerge, and it’s crucial for industries to explore and adopt these ideas to optimize their systems. Consulting with experts in dust collection system design and maintenance can also help ensure that the system is operating at maximum efficiency and effectiveness.

In summary, innovative dust collection design ideas offer significant benefits for industries seeking to improve their dust collection systems’ efficiency and effectiveness. By considering the key factors outlined in this post, exploring new design ideas, and consulting with experts, industries can optimize their dust collection systems and promote a safe and healthy work environment for their workers.