The baghouse system is one of the most popular types of air pollution control systems. It can be used to control a wide variety of pollutants, including particulate matter, volatile organic compounds, and hazardous air pollutants. The baghouse system works by using a series of filters to trap contaminants in the exhaust gas stream. The filtered gas then passes through a series of post-treatment devices before it is discharged into the atmosphere.

The basic principle of a baghouse system is simple: contaminated air enters the system and passes through one or more filter bags that capture large particles and dust. The clean air then exits the baghouse, often passing through additional air pollution control equipment for further treatment. In order to ensure effective operation, it is important that the filter bags are regularly replaced or cleaned. Read through to learn more about how the baghouse system works.

The baghouse system removes particulates from the exhaust gas of industrial facilities

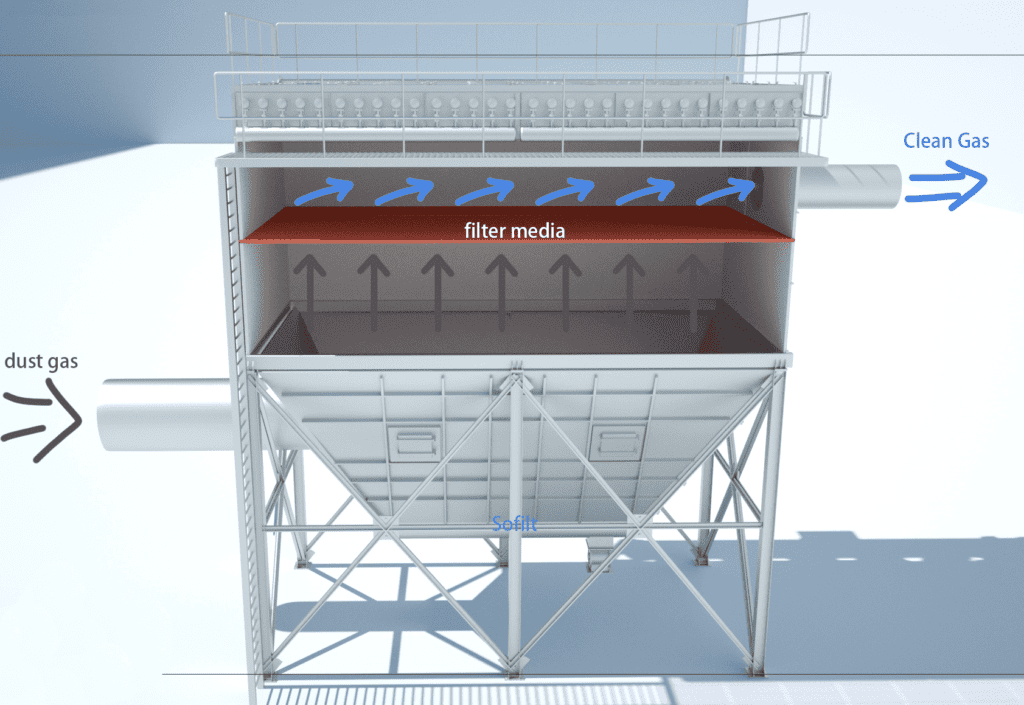

The baghouse system is a type of air pollution control device that has been gaining popularity due to its significant efficiency in removing particulates from the exhaust gas of industrial facilities. It works by introducing an upward airflow within a housed space, which causes dust particles to become “strained out” of the airflow due to their weight and size balance.

This process creates what is known as filter bags, which catch and collect the particulate matter for efficient disposal. Baghouses are highly efficient at collecting particulates, with collection efficiencies upwards of 99 percent. Additionally, they have minimal pressure drop, so that the exhaust gas passes through with minimal hindrance or additional power requirements.

With its simple design, it’s no wonder that the baghouse system has become such an important part of air pollution control in industrial settings: it helps prevent environmental contamination and protects people from hazardous materials without creating excessive costs for operators.

The baghouse system draws the contaminated gas through a series of filters

Many industries rely on combustible materials and other gases to power their production processes, but along with the desired substances come contaminants. Fortunately, an efficient system exists to rid these industries of dangerous particulate matter—the baghouse system. This system works by drawing the contaminated gas through a series of small filters made of fabric or metal mesh.

As this pressurized air passes through the filters, the particulates are trapped and “filtered out”. The two most popular designs for the baghouse system are a “shaker style”, where mechanical arms shake off collected particulates from outside, and a “reverse air style” which uses fans to remove captured particles from the inside of bags.

Both styles use carefully designed filter media to pull out everything from sulfur dioxide to ash, metal shavings, and wood chips – all at levels far more efficient than those achieved with traditional methods like cyclones or centrifuges.

In addition, baghouses requiring minimal maintenance while boasting long life spans make them cost-effective solutions for particulate removal in any industry that produces air contaminants. All in all, baghouse systems represent a clean technology to combat dirty emissions and protect our environment now and into the future.

The baghouse system filtered gas is then discharged into the atmosphere

The baghouse system is an essential part of many industrial facilities, allowing them to safely and efficiently operate without negatively impacting their environment. This system filters out particulate matter, solids, and non-condensable gases from heated process air.

After the air passes through a series of filters, it can then be discharged into the atmosphere–a process known in some cases as stack-gas emission. On its way out, however, the gas must still adhere to certain standards and limits imposed by regulatory authorities such as the EPA (Environmental Protection Agency) in order to protect both human health and natural habitats.

These guidelines can vary depending on the location but are typically in place to maintain good air quality throughout communities situated nearby. Ultimately, while the baghouse allows for productive operations within a facility, it also obligates companies to ensure that nothing harmful is emitted back into our shared atmosphere after passing through their system. As long as businesses strive for compliance with standard regulations, this type of particle separation can continue to support our economy without compromising our environment.

The baghouse system is effective at reducing emissions of harmful pollutants

The baghouse system of air pollution control system is increasingly being used to reduce emissions of harmful pollutants in industrial settings. It works by trapping particulate matter, sulfur dioxide, and nitrogen oxides in large filter bags with a variety of different filtration media.

The pollutants are drawn into the system via an induced-draft fan and then sent through the filter media which capture them on contact. This helps to create cleaner air and healthier working conditions for workers who may be exposed to these hazardous materials. As this technology continues to evolve and become more efficient, it could potentially play an even bigger role in helping to reduce emissions from industrial activities across the world.

With this technology becoming more widely used, it represents a positive step towards safeguarding air quality for generations to come. Additionally, many companies are finding that the use of this technology can lead to significant cost savings in their day-to-day operations as well as long-term environmental stewardship practices.

It’s clear that the baghouse system is not only effective at reducing harmful pollutants but also offers numerous benefits for industries that choose to incorporate it into their operations. All in all, it’s certainly an important tool for keeping our environments safe and healthy.

The baghouse system can be customized to meet the specific needs of an industrial facility

Industrial facilities often face unique challenges when it comes to finding a reliable way to monitor and manage particulates in the air. To ensure compliance with environmental regulations, it’s important to select the right system for the job. A baghouse is an effective and customizable solution for managing air pollution from dust, fumes, and other particles. Baghouses use filters made of cloth-like material which are installed within a ducted system.

The bags can be customized according to the size, shape, and kind of filter needed to meet the specific requirements of an industrial facility. By simply changing out filter media and adjusting filter cleaning cycles based on their particular needs, industrial facilities can be confident that their baghouse systems will provide efficient performance that meets environmental standards for particulate emissions. With proper maintenance and operation, baghouse systems are an affordable solution for ensuring that pollution levels remain in check.

Sofilt baghouse dust collector filter bags

Getting dust collector filter bags in the market is no longer a problem. Sofilt has been manufacturing and producing dust collector filter bags for over 15 years. We are one of the leading manufacturers in this area and have been providing customers with top-quality products that stand the test of time.

Our filter bags come in different materials such as polyester, PPS, P84, PTFE, fiberglass, acrylic, aramid, and nonwoven fabrics. We also manufacture cages, filters, and fiberglass needles to accompany our bags. All of our products are made with high-quality materials that can ensure the best results. With the help of advanced technology, we make sure that our dust collector filter bags meet industry standards and provide maximum efficiency at all times.

If you are looking for dust collector filter bags that are reliable, durable, and efficient, then Sofilt is the perfect choice for you. We have a wide variety of products that can meet your needs no matter how big or small they may be.

Our goal at Sofilt is to keep working hard to provide customers with the best dust collector filter bags on the market. Our team is always striving to improve our products and services so that we can continue to meet the needs of our customers. We look forward to hearing from you and helping you find the perfect product for your industrial facility.

Conclusion

Baghouse systems are a reliable and effective way to reduce air pollution levels within industrial facilities. With the right selection of filter media and regular maintenance, baghouses can provide steady and reliable performance that meets environmental regulations.

Additionally, baghouse systems offer numerous benefits such as cost savings and long-term environmental stewardship practices. For those looking for a cost-effective and reliable system to manage air pollution, the baghouse is an excellent choice.

When it comes to finding the right filter bags for your baghouse system, Sofilt is here to help. We offer a wide variety of products that can meet the specific needs of any industrial facility. With our top-quality dust collector filter bags, you can be sure that your baghouse system will provide optimal performance and efficiency. Contact us today to find out more about our products and services.