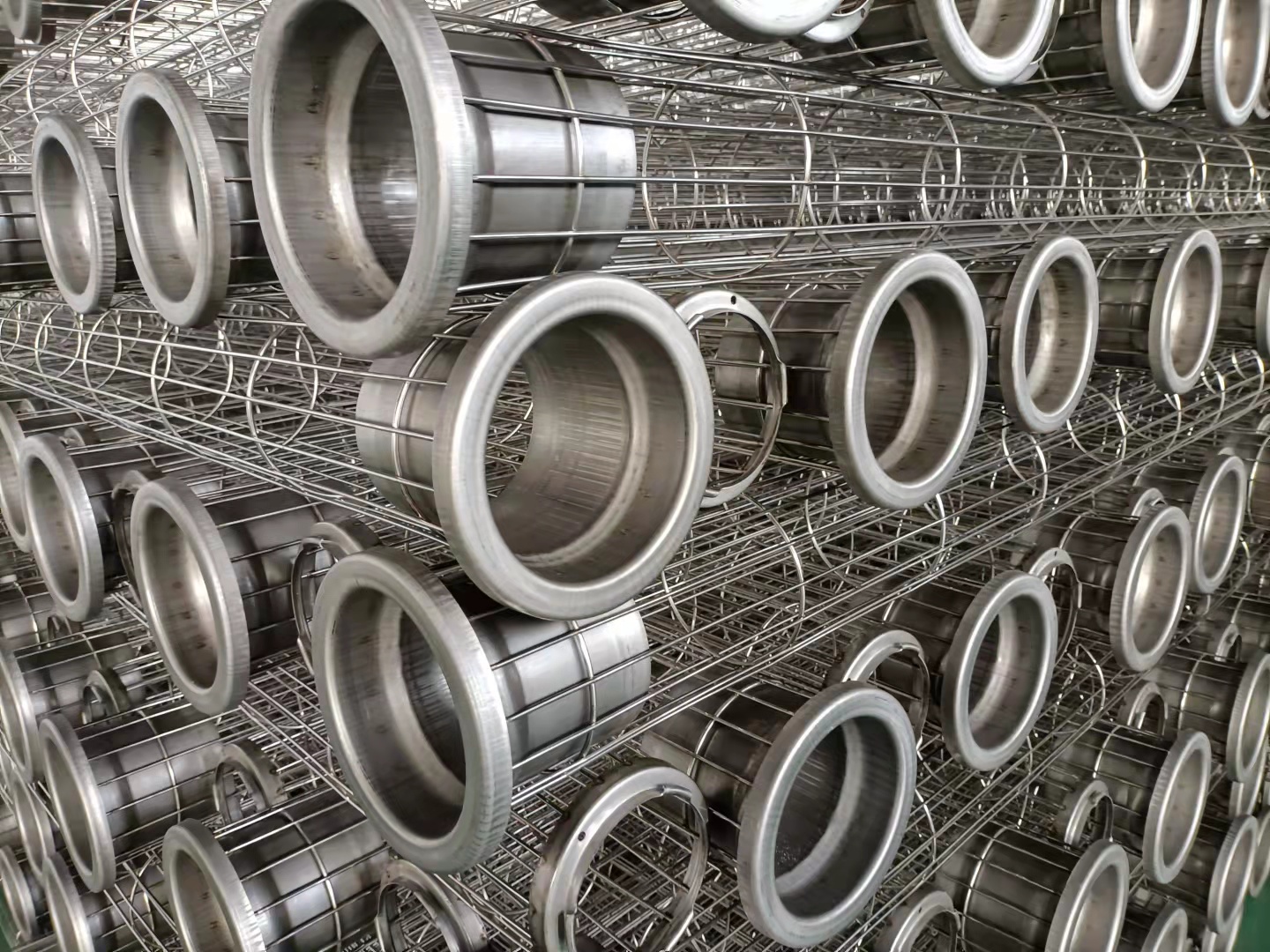

Filter Cage

The filter cage is a metal support that is used in the baghouse to support the filter bags. It is a common component of a baghouse.

Filter Cage

The filter cage is an accessory in the baghouse system. It serves to support the filter bag. They are made by welding metal wires. A matching filter cage plays a crucial role in the lifespan of the filter bag.

- Galvanized steel

- Carbon steel

- Mild steel

- 304 stainless steel

- 316 stainless steel

- Inconnel 600/601

- Epoxy coating

- Silicone coating

We can customize any size to suit you. And provide the drawings as well

- Round

- Oval

- Rectangle

- Envelope

- Star-shaped

The two-section interface is the most common type in the filter cage. This is convenient for installation and transportation in the long baghouse. They are usually composed of two parts that are joined together by a lock.

Specifications

| Types | Round, oval, diamond, pleated. | ||

| Wire Diameter | 3.0/3.2/3.5/3.8/4.0/5.0mm. | ||

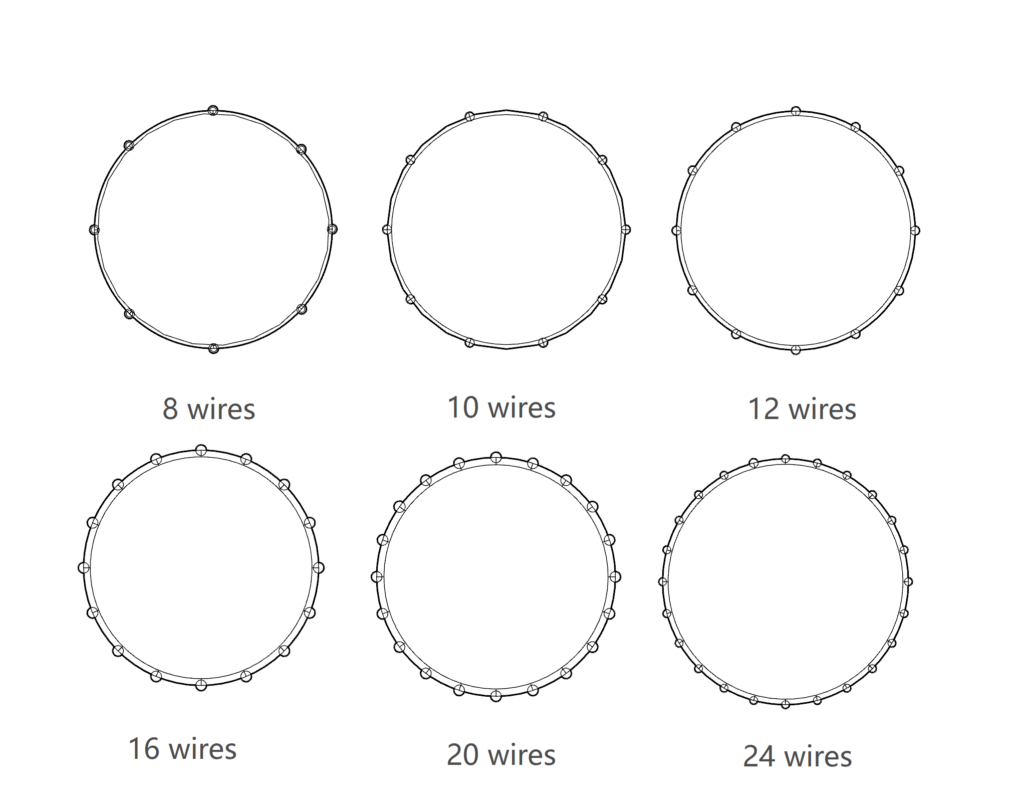

| Number of Wires | 8/10/12/16/20/24. | ||

| Ring Space | 6 inch or 8 inch.(15.24cm or 20.32cm) | ||

| Cage Diameter | 4 inch to 8 inch. (100mm to 200mm) | ||

| Wire Thickness | 3 mm to 5 mm. | ||

| Material | Carbon Steel, Titanium Steel, Galvanized Steel, Stainless Steel. | ||

| Connection Methods | Flanges, collars, or venturis. | ||

| Finishment | Epoxy, silicon, coating. | ||

Ultimate Guide for

Filter cage

Filter bag cages are essential components in dust collection systems, particularly in baghouse filters. They provide structural support to the filter bags, ensuring they maintain their shape during operation and do not collapse under airflow or pressure. Cages can be customized in size, wire thickness, spacing, and surface treatment to meet specific operational needs.

Filmedia® supplies bag cages in various materials and shapes to meet different industrial application needs.

- Stainless Steel Cages.

- Galvanized Steel Cages.

- Titanium Steel Cages.

- Silicon Coated Cages.

- Pleated Cages.

Selecting or customizing your cages, consider these three factors:

1.Wire Count (Vertical Wires): Typically 8, 10, 12, or 20 wires. More wires provide better support for the bag, reducing the “flexing” that causes fabric fatigue.

2.Ring Spacing: Proper spacing prevents the bag from sagging between the rings, which is a common cause of poor dust release during cleaning cycles.

3Surface Finish: Burrs or rough welds are the enemy. High-quality cages use specialized welding techniques to ensure a smooth surface that won’t snag or tear the filter fabric.

Applications

- Cement plant

- Asphalt mixing station

- Waste incineration plant

- Thermal power plant

Filter Cage Comprehensive FAQ

A: A filter cage (also known as a dust collector frame) is the essential structural support inside a pulse-jet baghouse. Known as the “ribs” of the filter bag, it prevents the bag from collapsing under negative pressure during filtration, ensuring smooth airflow.

A: The number of vertical wires determines the level of support provided to the filter media:

8 / 10 Wires: Typically used for small-diameter bags ($120\text{–}130\text{mm}$) in light-duty applications.

12 / 16 Wires: The industry standard for most industrial baghouses, offering a perfect balance between support and airflow.

20 / 24 Wires: Used for large-diameter bags or high-pressure environments to provide high-density support and reduce “flex fatigue” on the fabric.

A: Selection depends entirely on your operating environment:

Carbon Steel: The most cost-effective choice for non-corrosive, ambient-temperature, and dry dust environments.

Stainless Steel (304 / 316L): Essential for high-acid/alkali environments, moisture-heavy conditions, or food-grade/pharmaceutical applications.

A: 1. Galvanized: Provides basic rust resistance; ideal for woodworking or construction dust. 2. Silicone Coating: The premium standard. Highly resistant to temperatures up to $200^\circ\text{C}$ and corrosion. Its smooth finish minimizes friction against the filter bag. 3. Epoxy/Powder Coating: Offers good physical impact resistance and aesthetics, suitable for low-to-medium temperature environments.

A: If a cage is bent or tilted, it causes:

Mechanical Wear: Adjacent bags may rub against each other, leading to premature tearing.

Cleaning Inefficiency: Uneven spacing prevents effective pulse-jet cleaning.

Installation Issues: Difficulty fitting the cage into the tubesheet/flower plate.

A: A Venturi is a nozzle-shaped component installed at the top of the cage. It directs the pulse-jet air, increasing the pressure of the cleaning blast to ensure it reaches the bottom of long bags.

Recommended: For bags longer than 3 meters or when high-pressure cleaning is required.

A: Excluding chemical factors, cage-related causes usually include:

Burrs & Sharp Welds: Poor welding quality creates sharp edges that slice the fabric during pulse cycles.

Rust/Corrosion: Surface treatment failure causes the bag to stick to the cage; when cleaning occurs, the fabric fibers are torn away.

Improper Sizing: A cage that is too loose fails to support the bag; one that is too tight overstretches the fabric.

A: Under normal conditions with proper material matching:

Galvanized: 2–3 years.

Silicone Coated / Stainless Steel: 5+ years.

A: To ensure a perfect fit, please provide:

Number of vertical wires and wire diameter (e.g., $3.2\text{mm}$ or $4.0\text{mm}$).

Total length and outer diameter of the cage.

Top style (e.g., Rolled flange, Split collar, or Star top).

Bottom style (e.g., Welded cap or U-bottom).

Section count (Single piece or multi-section interlocking cages).

Operating conditions (Temperature, humidity, and chemical presence).

1.Operating Principles of Filter Cages

Structural Support (Negative Pressure): During filtration, dust-laden air moves from the outside of the bag to the inside (out-flow filtration). This creates an inward pressure. The cage, with its vertical wires and horizontal rings, provides rigid support to prevent the bag from collapsing, ensuring the filtration channel remains open.

Cleaning Assistance (Positive Pressure Pulse): When the pulse valve releases a blast of compressed air, the filter bag expands rapidly. When the air stops, the bag snaps back against the cage. This “expansion-contraction” cycle shatters the dust cake on the exterior of the bag so it can fall into the hopper.

Airflow Induction (Venturi Effect): The Venturi at the top uses the Bernoulli principle to direct the pulse-jet air precisely down the center of the bag, inducing secondary air to ensure the cleaning energy reaches the very bottom of the bag.

2. Installation Guide

Proper installation is the single most important factor in determining the lifespan of your filter bags.

Phase 1: Pre-Installation Inspection

Burr Check: Wear a pair of fine silk or knit gloves and slide your hand firmly up and down the cage. If the glove snags or tears, there is a welding burr that must be ground smooth, or it will slice the filter bag.

Straightness Check: Stand the cage on a level floor. Any visible tilt or “banana” curve will cause the bags to rub against each other, leading to holes.

Phase 2: Installation Procedure

Bag Insertion: First, seat the filter bag into the tubesheet hole, ensuring the snap-band creates a perfect, airtight seal.

Cage Insertion: Lower the cage slowly and vertically into the bag. Never force or drop the cage into the bag, as the weight can damage the bottom of the filter media.

Alignment: Ensure the bottom cap of the cage is centered. For multi-section cages, ensure the joints (claw-type, slide-lock, or threaded) are fully engaged and locked.

Securing: Firmly lock the cage top into the tubesheet to prevent “jumping” during high-pressure pulse cycles.

3. Maintenance & Troubleshooting Guide

Regular inspections prevent catastrophic failures and unplanned downtime.

Regular Maintenance Tasks

Corrosion Inspection: Check the surface coating (Galvanized or Silicone) annually. If widespread rust is found, it indicates a change in flue gas chemistry (acid dew point), and a material upgrade is required.

Weld Integrity: Check the intersection points of wires and rings. A broken weld can act like a needle, puncturing the bag during the pulse cycle.

Bottom Wear: Inspect the bottom of the bags. Excessive wear here often suggests the cage is vibrating too much or is slightly too long for the baghouse casing.

Troubleshooting Table

Symptom Potential Cause Solution Vertical scratches inside the bag Burrs on welds or rusted vertical wires Smooth the welds or upgrade to silicone-coated cages Poor cleaning / High pressure drop Loose or misaligned Venturi Secure and re-align the Venturi nozzle Cage deformation/Warpage Gas temperature exceeding material limits Upgrade to Stainless Steel or increase wire thickness Loose bag fitment Diameter mismatch between bag and cage Re-measure and verify tolerances (usually $\pm 1\text{mm}$)