Introduction

Dust collection systems are an essential component of many industrial facilities, woodworking shops, and other businesses that produce dust and other airborne particles. These systems are designed to capture and remove dust and other particles from the air before they can be inhaled by workers or escape into the environment. An effective dust collection system can help protect workers’ health, improve air quality, and prevent equipment damage.

Designing an effective dust collector involves several factors, including the type of dust produced, the size of the facility, the type of equipment used, and the layout of the workspace. In this article, we will discuss these factors in detail and provide tips for designing an adequate dust collection system.

Types of Dust Collection Systems

Before designing a dust collector, it’s essential to understand the types of dust collection systems available. The three main types of dust collection systems are:

Cyclone Dust Collectors

Cyclone dust collectors are air handling systems designed to remove large particles from the air using centrifugal force. These systems use a cyclonic action to separate the dust and other particles from the air, which are then collected in a bin or drum for disposal. Cyclone dust collectors are an excellent choice for large facilities that experience a lot of dust accumulation.

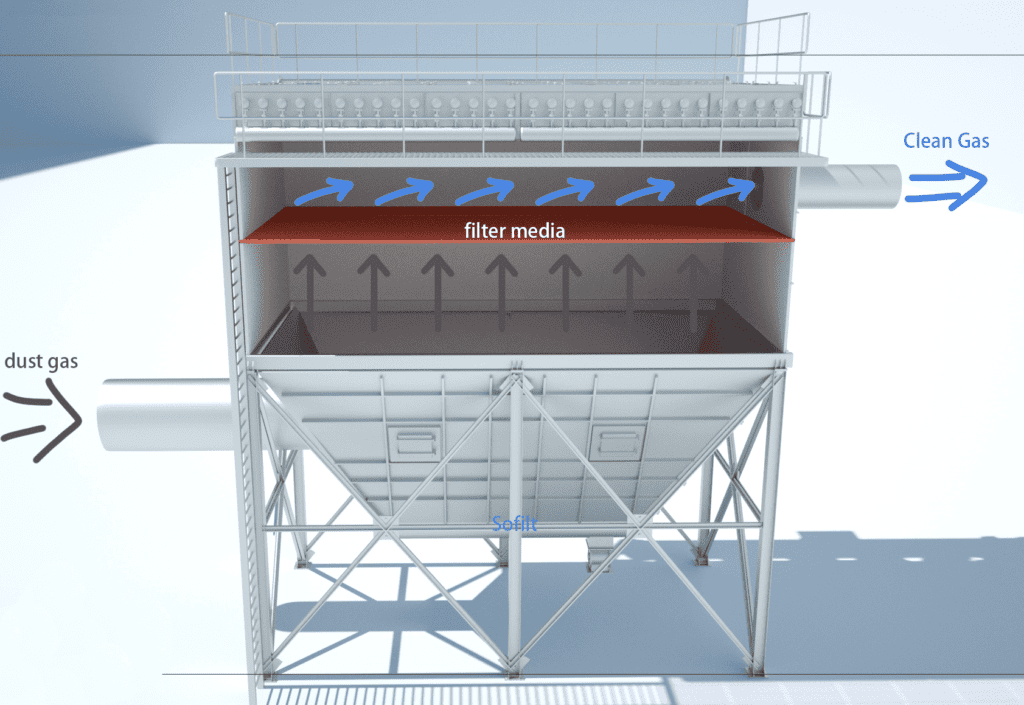

Baghouse Dust Collectors

Baghouse dust collectors are dust collection fittings designed to remove fine particles from the air. These systems use fabric dust collector filter bags to capture dust and other particles as they pass through the system. Baghouse dust collectors are an excellent choice for facilities that produce fine dust, such as metalworking shops or pharmaceutical companies.

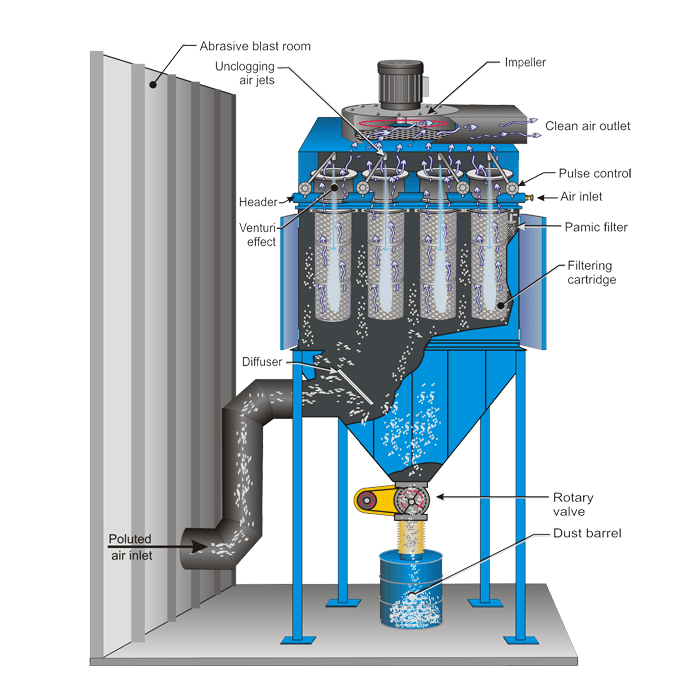

Cartridge Dust Collectors

Cartridge dust collectors are similar to baghouse dust collectors, but they use cartridges instead of bags to capture dust and other particles. Cartridge dust collectors are an excellent choice for facilities that produce small or fine particles, such as woodworking shops or plastic manufacturing plants that need an effective dust collection performance.

Factors to Consider When Designing a Dust Collection System

When designing a dust collector system, there are several factors to consider, including:

Type of Dust Produced

When designing a dust collection system, one of the critical factors to consider is the type of dust produced by the process or equipment generating the dust. This is important because different types of dust have different physical and chemical properties, which can affect the selection of equipment, system design, and filtration options.

Different types of dust require different types of dust collection systems. For example, large dust particles can be captured using a cyclone dust collector, while fine dust particles require a baghouse or cartridge dust collector.

Here are some key considerations to keep in mind regarding the type of dust produced:

- Particle Size: Dust particles vary in size, ranging from large to small particles. The particle size is essential because it determines the type of filtration needed to capture the dust effectively. For instance, larger particles may require a pre-filter before the air is passed through the primary filter.

- Dust Characteristics: The characteristics of the dust, such as its abrasive or corrosive nature, can affect the type of equipment used in the system. For example, corrosive dust may require the use of specialized materials or coatings for the ductwork and filters to prevent damage or corrosion.

- Explosive Dust: If the dust produced is explosive, the dust collector must be designed to prevent explosions. This can be achieved through the use of explosion-proof equipment, such as spark arrestors, explosion vents, or isolation systems.

- Hygroscopic Dust: Some types of dust are hygroscopic, meaning they absorb moisture from the air. Hygroscopic dust can become sticky and clump together, making it more difficult to capture and filter. In such cases, a system that includes a dehumidifier may be necessary.

- Toxic Dust: If the dust produced is toxic, the system must be designed to protect workers and the environment. This may require specialized equipment, such as HEPA filters or air scrubbers, to remove harmful particles from the air.

Size of Facility

The size of the facility is another essential factor to consider when designing a dust collector. Larger facilities require larger dust collection systems, while smaller facilities can use smaller systems. The size of the system will also depend on the type of equipment used in the facility.

The size of the facility will determine the amount of dust produced and the necessary airflow needed to collect the dust effectively. Here are some points to consider:

- Dust production: The amount of dust produced by the facility will determine the size and capacity of the dust collection system. Larger facilities typically produce more dust and require larger systems to handle the volume of dust produced.

- Airflow: The size of the facility will determine the necessary airflow needed to effectively collect the dust. The airflow is calculated based on the volume of the facility and the amount of dust produced. If the airflow is not sufficient, the dust will not be effectively collected.

- Ductwork: The size of the facility will also impact the ductwork required for the dust collection system. Larger facilities require longer and larger diameter ductwork to effectively move the dust from the source to the collection system.

- Location: The location of the facility will impact the design of the dust collection system. Facilities in urban areas or near residential areas may have more stringent noise and emissions regulations, which will impact the type and design of the dust collection system.

- Maintenance: The size of the facility will impact the maintenance required for the dust collection system. Larger facilities may require more frequent maintenance to ensure the system is operating effectively.

Type of Equipment Used

It is crucial to take into consideration the type of equipment used in the industrial setting. The reason for this is that different types of equipment produce varying amounts and types of dust, and as a result, each one requires a specific approach to effectively collect the dust.

For instance, dust-producing equipment like grinders, sanders, saws, and routers create a significant amount of dust during their operation. To design a dust collection system for such equipment, the size and type of dust produced, as well as the airflow required to effectively capture the dust, must be considered. Multiple collection points and ductwork may be necessary to capture the dust produced by this equipment effectively.

Other types of equipment that generate dust include pneumatic conveyors, mixers, and blenders. Such equipment produces dust as a result of material handling and processing. In this case, it is important to consider the design of the equipment and how it handles the material, as well as the type of dust generated, and its flow characteristics.

Additionally, the location and layout of the equipment are critical factors that must be considered when designing a dust collection system. The placement of the equipment in relation to the collection points and ductwork can affect the overall efficiency of the system. If the equipment is situated in a confined space, it may be necessary to use portable or flexible ductwork to capture the dust effectively.

Layout of Workspace

When designing a dust collection system, the layout of the workspace is an important factor to consider. The layout of the workspace can impact the effectiveness and efficiency of the dust collection system, as well as the overall safety and health of workers. The dust collection system must be designed to capture dust and other particles from all areas of the workspace. The system must also be designed to prevent dust from accumulating in hard-to-reach areas.

Firstly, the location of the dust-producing equipment within the workspace is critical. Dust-producing equipment should ideally be placed away from other work areas to minimize exposure to workers. If the equipment is located in an area with high traffic flow, it can cause dust to spread throughout the workspace, making it challenging to control. When designing a dust collection system, the location of the equipment should be taken into account to ensure that the collection points and ductwork are appropriately placed to capture the dust at the source.

Secondly, the layout of the workspace can affect the airflow and ventilation requirements of the dust collection system. If the workspace is large or irregularly shaped, it may be necessary to use multiple collection points and ductwork to ensure that all areas are adequately covered.

Additionally, the number of workers and the type of work being performed in the workspace can impact the airflow and ventilation requirements of the dust collector system. For instance, if the workspace has high traffic flow, the dust collection system must be designed to handle the increased airflow and dust generation.

Lastly, the layout of the workspace can affect the type of dust collection equipment that is required. For instance, if the workspace has limited space, portable dust collectors or compact dust collection units may be necessary to capture the dust effectively. Conversely, if the workspace is large, it may be more efficient to use a central dust collector with multiple collection points and ductwork.

Tips for Designing an Effective Dust Collection System

Now that we have identified the factors to consider when designing a dust collection system, let’s look at some tips for designing an effective dust collection system:

Conduct a Dust Hazard Analysis

Before having a dust collection system design, it’s essential to conduct a dust hazard analysis to identify the hazards associated with the dust produced in the facility. The analysis should identify the type of dust produced, the location of the dust generation source, and the potential risks associated with the dust. This information will help determine the type of dust collection system required.

This analysis involves identifying the sources of dust in the workplace, evaluating the potential risks associated with the dust, and determining the appropriate controls to reduce or eliminate those risks.

Conducting a dust hazard analysis helps to identify the sources of dust in the workplace. This includes the type and quantity of dust produced, as well as the equipment and processes that generate the dust. Identifying these sources is crucial to design an effective dust collection system because it helps to determine the size, type, and location of the collection points and ductwork required to capture the dust at the source.

A dust hazard analysis evaluates the potential risks associated with the dust. Dust can pose a significant health and safety hazard to workers if it is not controlled properly. Respiratory problems, skin irritation, and eye irritation are just a few of the health issues that can result from exposure to dust. A dust hazard analysis helps to identify these risks and determine the appropriate controls to reduce or eliminate them.

Conducting a dust hazard analysis helps to determine the appropriate controls for reducing or eliminating the risks associated with dust. This includes selecting the appropriate dust collection equipment, determining the airflow and ventilation requirements, and identifying any additional safety measures that may be required. By implementing these controls, the risk of dust-related hazards can be significantly reduced, providing a safe and healthy working environment for employees.

Choose the Right Type of Dust Collection System

Choosing the right dust collection system design is another important factor to consider when designing your effective dust collection system. The type of dust collection system you choose will depend on several factors, including the type of dust or debris you need to collect, the volume of dust or debris, the size and layout of your facility, and the specific requirements of your operation.

Here are some tips for choosing the right type of dust collection system:

- Determine the type of dust or debris you need to collect: The type of dust or debris you need to collect will determine the type of dust collection system you need. For example, if you are collecting fine dust particles, you may need a system with a high-efficiency filter, such as a HEPA filter, while if you are collecting larger debris, you may need a system with a larger collection bin or hopper.

- Consider the volume of dust or debris: The volume of dust or debris you need to collect will determine the size and capacity of the dust collection system you need. If you are collecting a large volume of dust or debris, you may need a system with a larger fan and motor, and a larger collection bin or hopper.

- Evaluate the size and layout of your facility: The size and layout of your facility will also play a role in determining the type of dust collection system you need. If you have a large facility with multiple workstations or production lines, you may need a centralized dust collection system with ductwork and multiple collection points. If your facility has limited space, you may need a compact, mobile dust collection system that can be easily moved from one location to another.

- Consider the specific requirements of your operation: The specific requirements of your operation, such as the need for explosion-proof equipment, may also dictate the type of dust collection system you need. For example, if you are collecting dust from a potentially explosive material, you may need a system with explosion-proof motors and components.

Overall, choosing the right type of dust collection system is crucial for ensuring the safety and efficiency of your facility. By considering the factors mentioned above and working with a knowledgeable dust collection system supplier, you can design an effective dust collection system that meets your specific needs and requirements.

Size the System Correctly

The size of dust collection system must be correctly sized for the facility. An undersized system will not effectively capture all the dust produced, while an oversized system will be expensive and inefficient to operate. To size, the system correctly considers the type of equipment used in the facility, the size of the facility, and the amount of dust produced. It is essential to ensure that the system is appropriately sized to handle the amount of dust and debris generated by the equipment in use.

An undersized system will not be able to capture and contain all the dust and debris generated by the equipment. This will result in dust and debris being released into the air, creating an unsafe and unhealthy work environment. The undersized system will also not be able to effectively filter the air, resulting in dust and debris buildup in the system’s filters and ductwork.

On the other hand, an oversized system may seem like a good idea as it can handle more dust and debris. However, an oversized system will be more expensive to install and operate than necessary. It will also create more noise and consume more energy than necessary, which can result in unnecessary expenses.

Therefore, it is important to properly size the dust collection system to optimize its efficiency and effectiveness. The size of the system should be determined based on the amount of dust and debris generated by the equipment, the size of the space where the system will be installed, and the airflow required to effectively capture and contain the dust and debris.

It is also important to consider the type of equipment in use and the type of dust and debris generated. For example, a system designed for capturing fine dust particles will require higher airflow rates than a system designed for capturing larger debris.

Choose the Right Ductwork

The ductwork must be designed to carry the dust and other particles from the source to the dust collection system effectively. The duct size should be correct to ensure that the system operates efficiently. The ductwork should be made from durable materials that can withstand the abrasive nature of dust and other particles.

The ductwork in a dust collection system plays a critical role in ensuring that the system is efficient, effective, and safe. Choosing the right duct design will ensure that the system operates optimally, and the dust and debris are collected and contained properly.

There are several factors to consider when selecting the right ductwork for a dust collection system. These include the material of the ductwork, the diameter of the ductwork, and the layout of the ductwork.

First, the material of the ductwork is an essential factor to consider. The most common materials for ductwork are metal, PVC, and flexible hose. Metal ductwork is the most durable and suitable for high-temperature applications, whereas PVC ductwork is suitable for low-temperature applications. Flexible hose ductwork is suitable for applications that require mobility, such as portable dust collection systems.

Second, the diameter of the ductwork is another essential factor to consider. The diameter of the ductwork should be chosen based on the amount of airflow required for the system. An inadequate diameter will restrict airflow, reducing the system’s effectiveness, whereas an oversized diameter will increase system cost and reduce efficiency.

Lastly, the layout of the ductwork is also important to consider. The layout of the ductwork should be designed to minimize pressure drops and to prevent dust and debris from settling and accumulating in the ductwork. A well-designed duct layout ensures that the dust and debris are collected and contained effectively and safely.

Maintain the System Regularly

Maintaining the dust collection system regularly is essential to ensure that it operates effectively. The system should be inspected regularly for leaks or other issues that could affect its performance. The filters should also be replaced or cleaned regularly to ensure that they are capturing the dust effectively.

Dust collection systems are designed to capture and contain dust and debris generated by equipment. Over time, the system’s filters, ductwork, and other components can become clogged with dust and debris, reducing the system’s effectiveness and safety.

Regular maintenance of the system involves cleaning and replacing filters, inspecting and cleaning ductwork, and checking and maintaining the system’s components. This ensures that the system is functioning correctly, and any issues are addressed before they become a safety hazard.

Cleaning and replacing filters are essential maintenance tasks as clogged filters can reduce the system’s airflow, which reduces its effectiveness in capturing and containing dust and debris. Inspecting and cleaning ductwork also prevents dust and debris buildup that can reduce the system’s efficiency and effectiveness.

Additionally, checking and maintaining the system’s components, such as motors, fans, and controls, ensures that they are operating correctly and efficiently. A malfunctioning component can cause the system to operate inefficiently or not work at all, resulting in a hazardous work environment.

Regular maintenance also prolongs the life of the system and reduces the cost of repairs and replacements. A well-maintained system operates optimally, reducing the wear and tear on the components, thus extending their lifespan.

Use Proper Ventilation

In addition to a dust collection system, proper ventilation is also essential to ensure that workers are not exposed to harmful dust and other particles. The ventilation system should be designed to move air in and out of the facility effectively, ensuring that the air is clean and healthy for workers to breathe.

Ventilation in a dust collection system refers to the process of introducing clean air into the workspace and removing contaminated air from the workspace. The clean air is introduced through the use of an exhaust system, which pulls air from the workspace and filters it before releasing it back into the environment. The contaminated air is then transported through the ductwork and into the dust collection system, where it is filtered and contained.

Proper ventilation ensures that the air quality in the workspace is safe and healthy, protecting workers from exposure to hazardous dust and debris. It also helps to prevent dust and debris buildup in the workspace, reducing the risk of fires and explosions.

When designing a dust collection system, it is essential to consider the ventilation requirements of the workspace. Factors such as the size of the workspace, the amount of equipment in use, and the type of dust and debris generated should be considered when designing the ventilation system.

The size of the workspace determines the amount of airflow required to maintain proper ventilation. A smaller workspace may require a smaller exhaust system, while a larger workspace may require a larger system.

The amount of equipment in use also affects the ventilation requirements of the workspace. Equipment that generates a significant amount of dust and debris requires a more robust ventilation system than equipment that generates minimal dust and debris.

The type of dust and debris generated also affects the ventilation requirements. Hazardous materials require a more robust ventilation system than non-hazardous materials.

Train Workers on Proper Use

Finally, it’s essential to train workers on the proper use of the dust collection system. Workers should be trained on how to use the system correctly and how to recognize when it is not working effectively. This will help ensure that the system is used correctly and that workers are protected from the hazards associated with dust and other particles. Proper training ensures that workers understand how to use the system correctly, reducing the risk of accidents and injuries.

Training workers on the proper use of the system involves teaching them how to operate the equipment safely and how to maintain the system correctly. Workers should be educated on the potential hazards of working with dust and debris, including the risk of fires and explosions, and how to prevent them.

It is also essential to train workers on the proper use of personal protective equipment (PPE), such as respirators, goggles, and gloves. Workers should understand how to properly use, maintain, and store PPE to ensure that it provides adequate protection.

Additionally, workers should be taught how to recognize the signs of system failure, such as reduced airflow or excessive noise, and how to report issues to supervisors.

Regular refresher training should be provided to ensure that workers remain up-to-date on the proper use and maintenance of the system. This is especially important if new equipment is added to the system or if changes are made to the system’s configuration.

Properly trained workers are essential to the safe and effective operation of the dust collection system. They can identify and report issues, prevent accidents and injuries, and maintain the system correctly, ensuring that it operates at peak efficiency.

Conclusion

Designing an effective dust collection system requires careful consideration of several factors, including the type of dust produced, the size of the facility, the type of equipment used, and the layout of the workspace.

By following the tips outlined above, you can design a system that effectively captures dust and other particles, ensuring that workers are protected from the hazards associated with dust exposure.

A well-designed dust collection system can also improve air quality and prevent equipment damage, making it a valuable investment for any facility that produces dust and other airborne particles. Sofilt is determined to ensure that the highest standards of safety and efficiency are met.

We provide customized solutions for dust collection filter bags to ensure that workers are properly trained in their use. Contact us today to learn more about how we can help you create a safe and efficient work environment.