Introduction

Baghouse dust collectors and cartridge dust collectors are two common types of dust collection systems used to control and eliminate airborne dust particles in industrial and commercial settings. These systems are used in a variety of applications, including woodworking, metalworking, and manufacturing. The choice of which dust collector to use depends on the specific application and environment. In our blog today, we will discuss the differences between baghouse dust collectors and the factors to consider when selecting between them.

Differences Between Baghouse Dust Collectors and Cartridge Dust Collectors

Baghouse dust collectors are more efficient and can trap larger particles than cartridge dust collectors. They use fabric filter bags to capture dust particles, which are then discharged into a collection bin. Baghouse dust collectors are typically more expensive than cartridge dust collectors, but they require less maintenance.

Cartridge dust collectors use a series of cylindrical filters to capture dust particles. These systems are generally more compact than baghouse collectors and require less space for installation, but they have a lower capacity and are less efficient, meaning they can’t handle as many airborne particles. Cartridge dust collectors also require more frequent maintenance due to their smaller filters, which must be replaced more often.

Factors to Consider When Selecting Between Baghouse Dust Collectors and Cartridge Dust Collectors

When selecting between baghouse dust collectors and cartridge dust collectors, it is important to consider a variety of factors. These include;

Filtration Technique

One major difference between baghouse dust collectors and cartridge dust collectors is the way in which they filter the air.

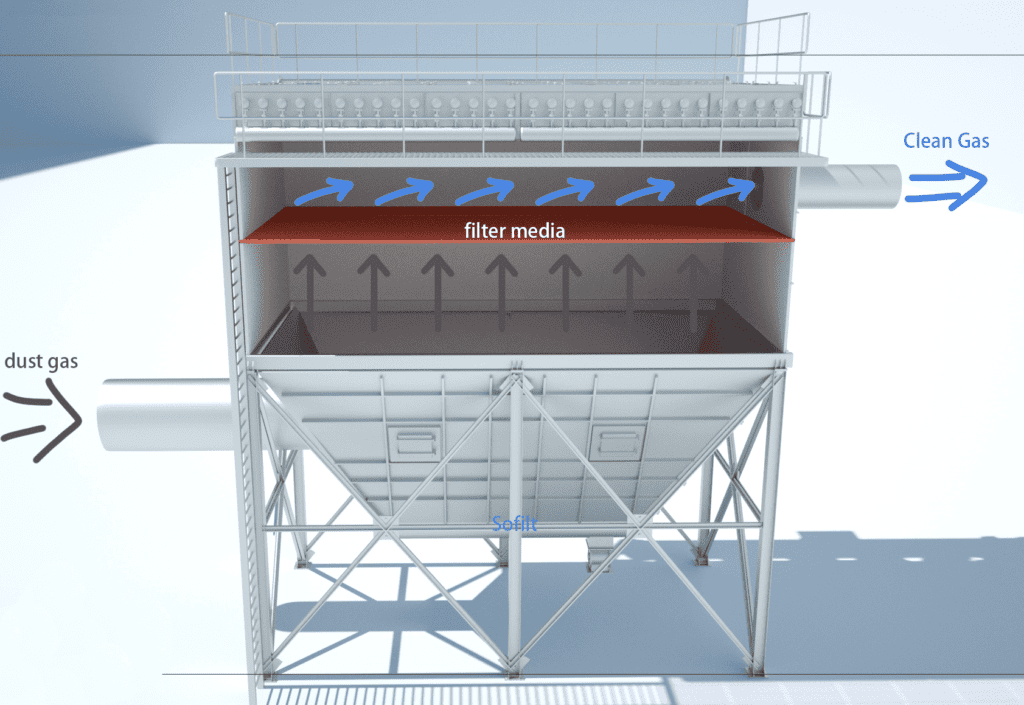

Baghouse dust collectors use fabric bags or tubes to capture the dust and particulates. These bags are typically made of a porous material such as fabric or felt, and they are suspended inside the collector. When the contaminated air passes through the bags, the dust and particulates are captured on the surface of the bags, and the clean air is released on the other side.

The bags or tubes can be made of different materials, depending on the specific needs of the application. For example, some baghouse dust collectors use bags or tubes made of a synthetic material such as polyester or cellulose, which are resistant to abrasive or corrosive dust. Other baghouse dust collectors use bags or tubes made of a natural material such as wool or cotton, which can be more effective at capturing fine dust particles.

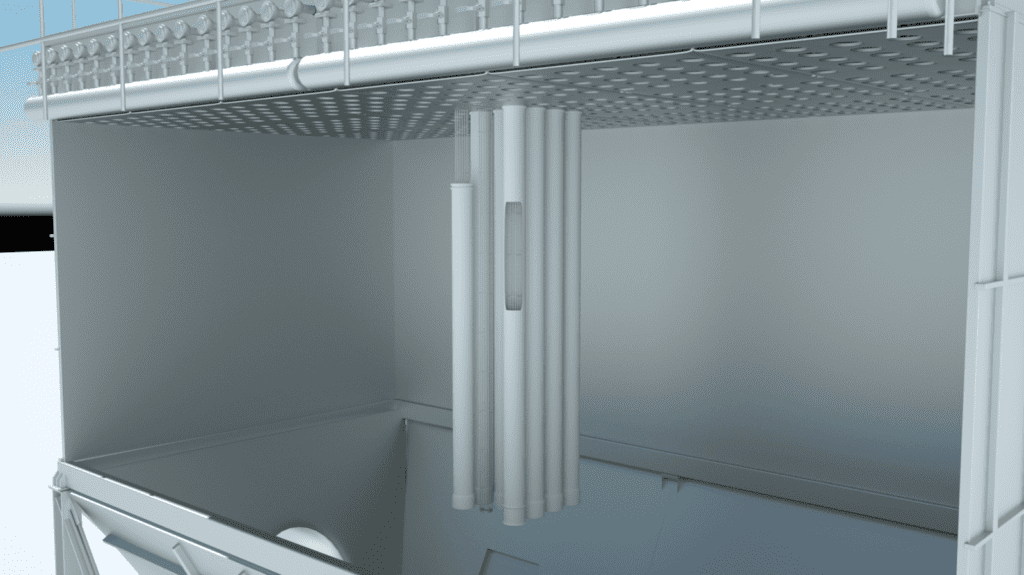

Cartridge dust collectors, on the other hand, use cylindrical cartridges filled with filter media to capture the dust and particulates. These cartridges are typically made of a synthetic material such as polyester or cellulose, and they are installed inside the collector.

When the contaminated air passes through the cartridges, the dust and particulates are captured on the surface of the filter media, and clean air is released on the other side. The cartridges can be easily removed and replaced when they become dirty or clogged, which makes cartridge dust collectors easier to maintain than baghouse dust collectors.

Size and Capacity

Another factor to consider when choosing between baghouse dust collectors and cartridge dust collectors is their size and capacity. Baghouse dust collectors are generally larger and more powerful than cartridge dust collectors, and they are capable of handling higher volumes of air. They are often used in industrial applications where large amounts of dust and particulates are produced, such as in cement plants or power plants.

Cartridge dust collectors, on the other hand, are generally smaller and more portable, and they are typically used in applications where space is limited or where the dust and particulate levels are lower. Cartridge dust collectors are often used in smaller manufacturing plants, woodworking shops, or other facilities where the dust and particulate levels are lower.

The size and capacity of a dust collector are important considerations because they can affect the efficiency and effectiveness of the collector. A larger, more powerful dust collector will be able to handle higher volumes of air and capture more dust and particulates, but it will also be more expensive to purchase and operate. A smaller, more portable dust collector may be more suitable for applications where space is limited or where the dust and particulate levels are lower, but it may not be as effective at capturing larger volumes of dust and particulates.

Maintenance and Replacement

Maintenance and replacement costs are another important consideration when choosing between a baghouse dust collector and a cartridge dust collector.

Baghouses:

- Maintenance: Baghouses typically require more frequent maintenance compared to cartridge dust collectors. The filter bags in a baghouse need to be cleaned or replaced on a regular basis, typically every 3-6 months depending on the dust load. This process involves removing the bags from the housing, shaking or beating them to remove the accumulated dust, and then replacing them. Baghouses also require regular inspections and repairs to ensure that they are operating efficiently and effectively.

- Replacement: When the filter bags in a baghouse reach the end of their service life, they need to be replaced. This process involves removing the old bags, installing new bags, and then reattaching them to the housing. Depending on the size of the baghouse and the number of bags, this process can be time-consuming and labor-intensive.

Cartridge dust collectors:

- Maintenance: Cartridge dust collectors typically require less frequent maintenance compared to baghouses. The cartridges in a cartridge dust collector can be cleaned by pulse jet cleaning, which involves injecting a burst of compressed air through the cartridges to blow off the accumulated dust. This process can be automated and does not require the cartridges to be removed from the housing. Cartridge dust collectors also require regular inspections and repairs to ensure that they are operating efficiently and effectively.

- Replacement: When the cartridges in a cartridge dust collector reach the end of their service life, they need to be replaced. This process involves removing the old cartridges, installing new cartridges, and then reattaching them to the housing. Depending on the size of the cartridge dust collector and the number of cartridges, this process can be less time-consuming and labor-intensive compared to replacing filter bags in a baghouse.

Overall, baghouse dust collectors tend to require more maintenance and replacement compared to cartridge dust collectors. However, the specific maintenance and replacement requirements will depend on the specific application, the dust load, and the operating conditions of the dust collector. It is important to consult with a knowledgeable manufacturer or engineer to determine the best dust collector for your specific application.

Durability

Both baghouse dust collectors and cartridge dust collectors are designed to be durable and long-lasting, and they can typically withstand the rigors of industrial environments. However, there are some differences in terms of their durability that are worth considering.

One factor that can affect the durability of a dust collector is the material of the filter media. Baghouse dust collectors use fabric bags or tubes to capture the dust and particulates, and these bags or tubes are typically made of a porous material such as fabric or felt. These materials can be durable, but they can also be prone to wear and tear over time, especially if they are subjected to abrasive or corrosive dust.

Cartridge dust collectors, on the other hand, use cylindrical cartridges filled with synthetic filter media such as polyester or cellulose. These materials are generally more resistant to wear and tear than fabric or felt, and they can often last longer in demanding industrial environments.

Another factor that can affect the durability of a dust collector is the frequency of maintenance and upkeep. Baghouse dust collectors generally require more frequent maintenance than cartridge dust collectors because the fabric bags or tubes need to be cleaned or replaced on a regular basis.

This can increase the wear and tear on the collector over time, which can shorten its lifespan. Cartridge dust collectors, on the other hand, are generally easier to maintain because the cartridges can be easily removed and replaced when they become dirty or clogged. This can help to extend the lifespan of the collector.

Both baghouse dust collectors and cartridge dust collectors are durable and long-lasting, but the specific durability of a particular collector will depend on the material of the filter media, the frequency of maintenance, and the specific conditions in which the collector is used.

Filtration Efficiency

Filtration efficiency is an important consideration when selecting a dust collector, as it determines the effectiveness of the device in removing particulate matter from the air. The filtration efficiency of a dust collector depends on a variety of factors, including the type and size of the filter media, the design of the dust collector, and the operating conditions.

Baghouses are typically equipped with filter bags made of woven or felted material, such as fabric or fiberglass. The pores in the filter material are designed to capture and retain particles of a certain size and type, depending on the specific application. Baghouses are generally effective at capturing and removing coarse to fine particulate matter, with typical efficiencies ranging from 85-99% for particles larger than 10 microns. However, baghouses may have lower filtration efficiency for smaller particles, such as those below 1 micron in size, due to the larger pores in the filter material.

Cartridge dust collectors on the other hand are equipped with filter cartridges made of pleated media, such as paper or synthetic fibers. The pleats in the media provide a larger surface area for capturing and retaining particles, which can result in higher filtration efficiency compared to baghouses. Cartridge dust collectors are generally effective at capturing and removing fine to ultrafine particulate matter, with typical efficiencies ranging from 95-99.9% for particles larger than 0.5 microns.

However, cartridge dust collectors may have lower filtration efficiency for larger particles, such as those above 10 microns in size, due to the smaller pores in the filter media.

It is important to note that the filtration efficiency of a dust collector can vary depending on the specific application, the dust load, and the operating conditions. It is always advisable to consult with a knowledgeable manufacturer or engineer to determine the best dust collector for your specific application and to ensure that it is operating efficiently and effectively.

Energy efficiency

When selecting a dust collector, it is important to consider energy efficiency as it can have a significant impact on the operating costs of the device over its lifetime. The energy efficiency of a dust collector depends on a variety of factors, including the size and design of the device, the type and size of the filter media, and the operating conditions.

Baghouses may need more energy to operate compared to cartridge dust collectors. This is due to the mechanical action of the filter bags, which need to be shaken or beaten to remove the accumulated dust. The energy required to operate a baghouse can vary depending on the size of the device and the dust load, but it is generally higher compared to cartridge dust collectors.

Cartridge dust collectors require less energy to operate compared to baghouses. This is due to the use of pulse jet cleaning, which involves injecting a burst of compressed air through the cartridges to blow off the accumulated dust. The energy required to operate a cartridge dust collector can vary depending on the size of the device and the dust load, but it is generally lower compared to baghouses.

It is important to note that the energy efficiency of a dust collector can vary depending on the specific application, the dust load, and the operating conditions. It is always advisable to consult with a knowledgeable manufacturer such as Sofilt or a qualified engineer to determine the best dust collector for your specific application and to optimize its energy efficiency.

Conclusion

Overall, the choice between a baghouse dust collector and a cartridge dust collector will depend on the specific needs and requirements of your application. The baghouse dust collectors and cartridge dust collectors are both effective at capturing and filtering dust and particulates from industrial processes. It is important to carefully evaluate all the above factors and consult with a dust collection specialist to determine the best solution for your specific needs.

Here at Sofilt, we offer a variety of dust collectors and air quality solutions to help you improve the air quality in your facility. We have decades of experience developing custom-engineered solutions for industrial applications, and we are confident that we can provide you with the best possible solution for your needs. Contact us today to learn more about our dust collection systems and how we can help you improve the air quality in your facility.