Introduction

Filter bag housing is a crucial component in the filtration process that plays a significant role in different industries. It is a type of equipment that is used to filter various substances to separate the solids from the liquids. The bag filter housing is designed to accommodate a filter bag that traps unwanted particles and allows the liquid to pass through.

The importance of filtration cannot be understated in various industries such as chemical, pharmaceutical, food and beverage, and many more. Filtration is a process that helps remove impurities and contaminants from liquids and gases to ensure the quality of the final product. It helps in maintaining a safe and healthy environment and ensures compliance with regulatory requirements.

The purpose of this blog is to provide information on the bag filter housing and how it can streamline your filtration process. We will discuss the features, benefits, and applications of filter bag housing and how it can help improve the quality and efficiency of your filtration process. By the end of this blog, you will have a better understanding of the importance of filter bag housing in the filtration process and how it can benefit your industry.

What is a Filter Bag Housing?

A filter bag housing is a type of filtration equipment used to remove solid particles from a liquid stream. It is commonly used in various industries such as chemical, pharmaceutical, food and beverage, and water treatment plants. Filter bag housing is designed to accommodate a bag filter and filter cartridge that captures the unwanted solids and allows the liquid to pass through.

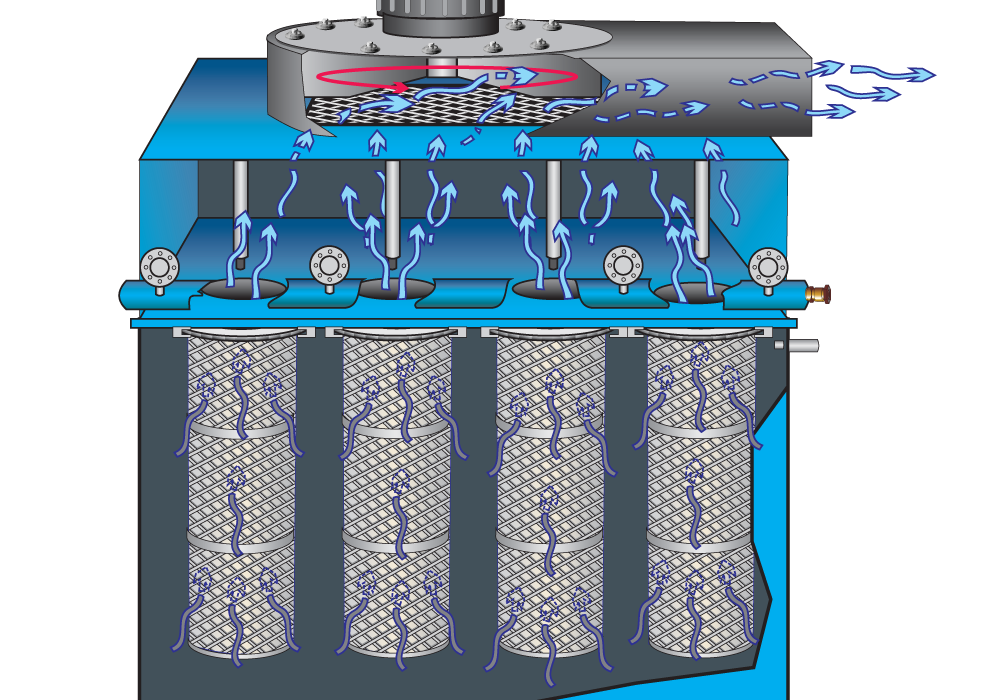

Components of Filter Bag Housing

The components of a filter bag housing play an essential role in the effective operation of the filtration process. Understanding the components of a filter bag housing is important in selecting the appropriate housing for a specific application. Here are the main components of a filter bag housing:

Vessel

The vessel is the main body of the bag filter housing and is typically made of materials such as carbon steel, stainless steel, or plastic. The vessel is designed to withstand high pressures and temperatures, ensuring the filter bag housing can operate in a wide range of applications.

Bag Support Basket

The bag support basket is an essential component of the bag filter housing. It holds the filter bag in place, ensuring that it does not collapse or burst during operation. The basket is designed to support the weight of the filter bag and the liquid or gas stream flowing through it. It is important to select a basket that matches the size and shape of the bag filter to prevent any damage to the bag or basket.

Lid

The lid is used to seal the filter bag housing and hold the filter bag in place. The lid typically has a gasket or O-ring that ensures a tight seal, preventing any leaks during operation for liquid bag filter housing. Some bag filter housings have a swing bolt design that allows for easy opening and closing of the housing for bag changeouts.

Inlet and Outlet Connections

The inlet and outlet connections allow for the flow of liquid through the filter bag housing. These connections are typically located on the top or bottom of the vessel and are designed to match the process piping. Some multi bag filter housing has multiple inlet and outlet connections to allow for different flow configurations.

Vent and Drain Connections

The vent and drain connections are used to release any trapped air or liquid from the filter bag housing. The vent connection is typically located on the top of the housing, while the drain connection is located at the bottom.

Overall, each component of a bag filter housing is designed to work together to ensure effective filtration and smooth operation. The selection of each component, including the size and material, is critical to achieving optimal performance and reducing maintenance downtime. Proper maintenance and cleaning of the filter bag housing components are also essential for the longevity and effectiveness of the filtration process.

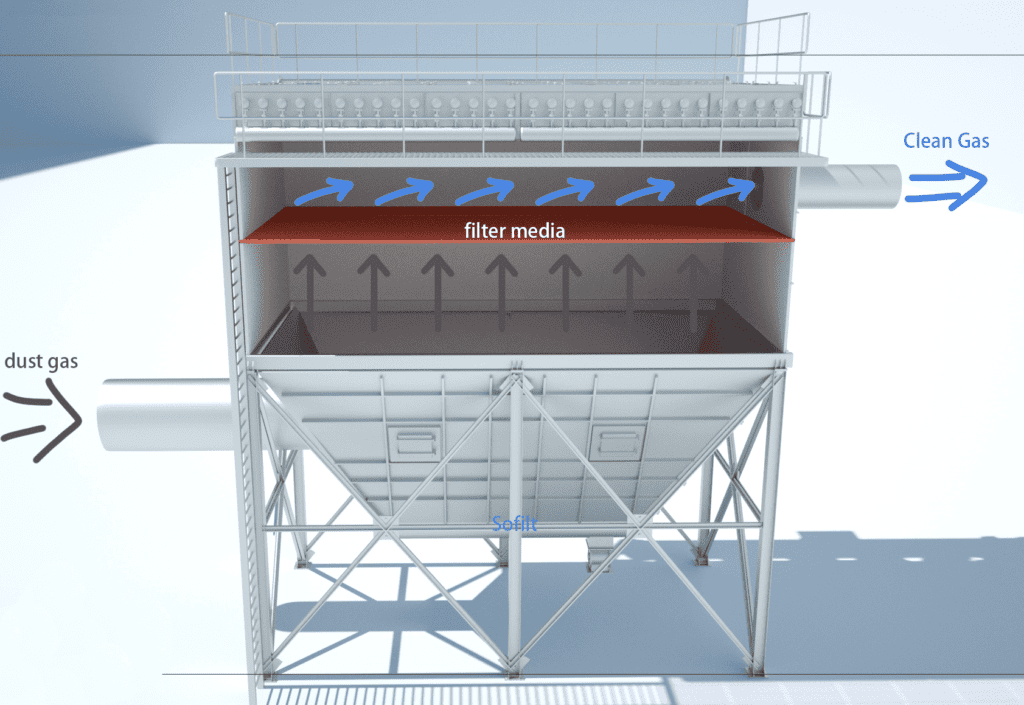

Types of Filter Bag Housing

There are various types of filter bag housing available, and the selection of the appropriate type depends on the specific application and process requirements. Here are the main types of bag filter housing:

Single Bag Housing

A single bag housing is designed to hold a single filter bag, and it is typically used in applications that require low flow rates or low volumes. It is compact, cost-effective, and easy to install and maintain. Single bag housings are commonly used in applications such as water treatment, food and beverage, and chemical processing.

Multi Bag FILTER Housing

A multi bag filter housing is designed to hold multiple filter bags, and it is typically used in applications that require high flow rates or high volumes. It is larger and more expensive than a single bag housing, but it offers a higher filtration capacity and reduces the need for frequent filter bag changeouts. Multi bag filter housing is commonly used in applications such as oil and gas, paint and coatings, and pharmaceuticals.

Duplex Bag Housing

A duplex bag housing consists of two single bag housings connected in parallel, and it is typically used for continuous filtration. While one housing is in operation, the other is being cleaned and serviced. The duplex bag housing allows for uninterrupted filtration, reducing downtime and increasing the efficiency of the process. Duplex bag housings are commonly used in applications such as wastewater treatment, petrochemicals, and pulp and paper.

Plastic Filter Bag Housing

A plastic bag filter housing is made of materials such as polypropylene or PVC, and it is typically used in applications that require resistance to corrosive chemicals or high temperatures. Plastic filter bag housings are lightweight, easy to install and maintain, and offer a cost-effective solution for filtration applications.

Sanitary Filter Bag Housing

A sanitary filter bag housing is designed for applications that require high levels of cleanliness and hygiene, such as food and beverage, pharmaceuticals, and biotech. Sanitary filter bag housings are made of materials such as stainless steel, and they are designed to meet stringent hygiene standards. They are easy to clean and sanitize, and they minimize the risk of contamination.

The selection of the appropriate type of bag filter housing is critical to achieving optimal filtration performance and reducing maintenance downtime. Each type of filter bag housing offers unique benefits and features that cater to specific process requirements. It is essential to work with an experienced filtration supplier who can assist in selecting the appropriate type of filter bag housing for your specific application.

Applications of Filter Bag Housing

Filter bag housing is a critical component of many industrial processes that require the filtration of liquids to remove contaminants, particles, or impurities. Here are some of the most common applications of bag filter housing:

Chemical Processing

Filter bag housing is widely used in the chemical processing industry to remove contaminants, solids, and impurities from liquids. Chemical processing often involves harsh chemicals and extreme temperatures, making it necessary to use a filter bag housing that can withstand these conditions.

Oil and Gas

The oil and gas industry relies heavily on filter bag housing for the filtration of crude oil, natural gas, and other process fluids. The filter bag housing is used to remove contaminants such as sand, dirt, and debris, ensuring that the fluid meets the required specifications for processing and transportation.

Food and Beverage

The food and beverage industry uses filter bag housing to ensure that the final product is free from contaminants, particles, and other impurities. This includes the filtration of water, juices, syrups, and other processed fluids that go into the production of food and beverages.

Pharmaceuticals

Filter bag housing is essential in the pharmaceutical industry, where a high level of purity is required in the production of drugs, vaccines, and other medical products. The bag filter housing is used to remove bacteria, viruses, and other contaminants from process fluids, ensuring that the final product is safe for human use.

Water Treatment

Filter bag housing is widely used in water treatment facilities to remove sediment, sand, and other impurities from water. This includes filtration of drinking water, wastewater, and other process fluids.

Automotive and Aerospace

The automotive and aerospace industries rely on bag filter housing to remove contaminants and impurities from hydraulic fluids, lubricants, and other process fluids. This ensures that the components and systems operate efficiently and meet the required specifications.

Filter bag housing is used in a wide range of industries and applications to ensure the effective filtration of liquids. The selection of the appropriate filter bag housing depends on the specific application and process requirements. Working with an experienced filtration supplier can help ensure that the appropriate bag filter housing is selected and optimized for your specific application.

By using filter bag housing, industries can improve the quality and efficiency of their filtration process, reduce downtime and maintenance costs, and protect downstream equipment from damage. With different types of bag filter housing available, it is important to select the right housing based on the specific requirements of the application.

Advantages of Using Filter Bag Housing

Filter bag housing provides several advantages over other filtration methods, making it a popular choice for many industrial applications. Here are some of the key advantages of using filter bag housing:

Improved Filtration Efficiency

Filter bag housing is designed to remove a wide range of contaminants, particles, and impurities from liquids. The filtration process is highly efficient, ensuring that the final product meets the required specifications. The filter bags themselves are made from a variety of materials, including polyester, nylon, and polypropylene, which are designed to capture particles of different sizes and densities.

Reduced Downtime

With bag filter housing, maintenance, and replacement can be carried out quickly and easily without the need for shutdowns or extended downtime. This is because filter bag housing typically has a modular design, which allows for easy replacement of individual filter bags without the need for disassembly. This means that maintenance and replacement can be carried out while the system is still operational, reducing downtime and increasing productivity.

Easy Maintenance and Cleaning

Filter bag housing is designed to be easy to maintain and clean, which helps to reduce the overall cost of ownership. The filter bags can be easily removed, cleaned, and replaced, and the housing can be easily disassembled for cleaning or maintenance. This reduces the need for specialized cleaning equipment or chemicals, making it a cost-effective filtration solution.

Cost-Effectiveness

Filter bag housing is generally more cost-effective than other filtration methods. This is because the filter bags themselves are relatively inexpensive, and the housing can be reused multiple times. Additionally, the modular design of filter bag housing means that individual components can be replaced as needed, rather than having to replace the entire system. This helps to reduce overall maintenance costs and increase the lifespan of the system.

Examples of these advantages can be seen in a variety of industries. For instance, in the food and beverage industry, the bag filter housing is used to ensure that the final product is free from contaminants, particles, and other impurities. The easy maintenance and cleaning of filter bag housing make it an ideal solution for this industry, where cleanliness and hygiene are critical.

In the chemical processing industry, the bag filter housing is used to remove contaminants and impurities from process fluids. The improved filtration efficiency of filter bag housing ensures that the final product meets the required specifications. The reduced downtime and easy maintenance of filter bag housing also make it an ideal solution for this industry, where process uptime and productivity are critical.

Filter bag housing provides several advantages over other filtration methods, including improved filtration efficiency, reduced downtime, easy maintenance and cleaning, and cost-effectiveness. These advantages make it a popular choice for a wide range of industrial applications, from food and beverage to chemical processing and beyond.

Factors to Consider When Choosing a Filter Bag Housing

When choosing a bag filter housing, there are several factors that need to be considered to ensure that it meets the specific requirements of the application. Here are some of the key factors to consider:

Size and Capacity

The size and capacity of the filter bag housing are important factors to consider, as they determine how much liquid the system can process at any given time. The size of the housing will depend on the flow rate of the liquid, while the capacity will depend on the volume of liquid that needs to be filtered. It’s important to choose a filter bag housing that can handle the required flow rate and volume to ensure optimal filtration performance.

Material of Construction

The material of construction is also an important factor to consider when choosing a bag filter housing. The housing should be made from a material that is compatible with the liquid being filtered and can withstand operating conditions. Common materials of construction include stainless steel, carbon steel, and plastic.

Filtration Rating

The filtration rating is a measure of the size of particles that can be removed by the filter bag. It’s important to choose a bag filter housing with the appropriate filtration rating for the application. If the filtration rating is too low, the filter may not be able to remove all of the particles and contaminants from the liquid. Conversely, if the filtration rating is too high, it may result in unnecessary pressure drops and increased operating costs.

Operating Temperature and Pressure

The operating temperature and pressure are important factors to consider when choosing a bag filter housing. The housing should be able to withstand the temperature and pressure of the liquid being filtered. If the temperature or pressure is too high, it can cause the housing to deform or fail, leading to system downtime and increased maintenance costs.

Environmental Factors

Environmental factors such as humidity, moisture, and exposure to corrosive chemicals can also affect the performance and lifespan of the bag filter housing. It’s important to choose housing that is designed to withstand these environmental factors to ensure optimal performance and longevity.

In the oil and gas industry, filter bag housing must be able to withstand high temperatures and pressures, as well as exposure to corrosive chemicals. The housing material must also be compatible with the type of fluid being filtered. In the food and beverage industry, the filtration rating is an important factor to consider, as it determines the level of purity of the final product.

The housing must also be easy to clean and maintain to ensure that it meets hygiene standards.

Choosing the right bag filter housing is critical to ensuring optimal filtration performance and minimizing downtime and maintenance costs. Factors such as size and capacity, material of construction, filtration rating, operating temperature and pressure, and environmental factors should all be carefully considered when selecting a filter vessel for a particular application.

How to Streamline Your Filtration Process with Filter Bag Housing

Filter bag housing can help streamline your filtration process by improving efficiency, reducing downtime, and increasing the lifespan of your filtration system. Here are some key steps you can take to optimize your filtration process with bag filter housings:

Proper Installation and Setup

Proper installation and setup of your bag filter housing are crucial to ensuring optimal filtration performance. This includes ensuring that the housing is correctly installed and connected to the filtration system and that the appropriate filters and bags are installed. Proper installation also involves ensuring that the housing is correctly aligned and that all seals and connections are tight.

Choosing the Right Filter Bag and Housing for Your Application

Choosing the right filter bag and housing is critical to ensuring optimal filtration performance. This involves considering factors such as the type of liquid being filtered, the filtration rating required, and the operating conditions. It’s important to choose a bag filter and housing that is compatible with the liquid being filtered and can withstand operating conditions.

Regular Maintenance and Inspection

Regular maintenance and inspection of your filter bag housing can help prolong the lifespan of your filtration system like the cartridge filters and bag filters and ensure optimal performance. This includes regularly changing the filter bags and cleaning the housing to prevent clogging and contamination. It’s also important to inspect the housing regularly for any signs of damage or wear and tear and to replace any damaged parts as needed.

Troubleshooting Common Issues

Despite proper installation, setup, and maintenance, issues may still arise with your bag filter housing. Common issues include leaks, clogging, and pressure drop. It’s important to troubleshoot these issues promptly to prevent system downtime and ensure optimal performance. This may involve replacing damaged parts, adjusting the filtration system settings, or changing the filter bag.

Industrial bag filter housing can be an effective tool for streamlining your filtration process. Proper installation and setup, choosing the right cartridge filter and housing, regular maintenance and inspection, and troubleshooting common issues are all critical steps in optimizing the performance of your filtration system. By taking these steps, you can improve efficiency, reduce downtime, and increase the lifespan of your filtration system.

Conclusion

Filter bag housing is an essential component of any filtration system, helping to improve filtration efficiency, reduce downtime, and increase the lifespan of your equipment. In this article, we’ve covered several key points about bag filter housing, including its definition, components, types, applications, advantages, factors to consider when choosing, and how to streamline your filtration process.

By using filter housings, you can optimize your filtration system, ensuring that it performs at peak efficiency and delivers high-quality, contaminant-free liquids. This is critical in many industries, where the purity and consistency of liquids can impact product quality, safety, and regulatory compliance.

We encourage you to explore your options for bag filter housing and consider how it could benefit your filtration process. Whether you’re working in automotive, pharmaceutical, food and beverage, or another industry, there is a bag filter housing solution that can meet your needs.

In conclusion, the bag filter housing is a powerful tool for optimizing your filtration process. By choosing the right housing and filter bag, performing regular maintenance and inspection, and troubleshooting common issues, you can achieve the highest levels of filtration efficiency and productivity. Take action today and explore the many options available for bag filter housing.